What requirements should the solder joints of lead-free solder meet?

![]() 2024.4.18

2024.4.18

Articles

Articles

In 2003, the European Union announced a significant policy, indicating the implementation of the RoHS directive ("Restriction of Hazardous Substances") for electronic products starting in 2006.

For the general production process adhering to RoHS standards, what specific requirements are necessary to meet the standard, and are there any changes in the production process?

1、Requirements for Solder Joints

1-1. Smooth and Rounded :

Weld points should be smooth and rounded, free from defects such as burrs, pores, recesses, and flux stains.

1-2. Uniform Solder Wetting :

Weld points should exhibit uniform solder wetting, exposing the metal framework without solder heap formation.

1-3. No Sharp Edges or Pores :

The surface solder on weld points should be even, without sharp edges or pores.

1-4. No Cold Joints :

Weld points should not exhibit cold joint phenomena; there should be full contact between the solder and component pins, with no gaps.

1-5. Aesthetic :

Weld points should have a pleasing appearance, free from any quality defects such as cracks.

1-6. Solder Joint Strength :

The soldered connections should possess sufficient strength to withstand the required mechanical stresses, such as vibration, tension, and pressure. Lead-free solder should be capable of providing solder joint strength comparable to that of lead-containing solder.

1-7. Temperature Characteristics :

Solder joints should be able to operate stably under different temperature conditions while maintaining the integrity of their connections. This is particularly crucial as some applications may require operation in high or low-temperature environments.

1-8. Thermal Stress :

The heat generated during the soldering process and the thermal stress during the cooling of solder joints can impact their stability. Lead-free solder should exhibit lower thermal stress to reduce the risk of solder joint damage.

1-9. Reliability :

Solder joints should possess good long-term reliability, resisting crack formation or deformation, which is especially vital for electronic products intended for prolonged operation.

1-10. Environmental Friendliness :

Solder joints should comply with environmental standards and should not contain substances harmful to the environment. This is a primary objective of lead-free solder, aiming to minimize environmental pollution.

1-11. Good Wettability :

Solder should exhibit good wettability, allowing it to uniformly cover the soldering surface, forming a reliable connection.

1-12. Ease of Operation :

The soldering process should be easy to operate, ensuring production efficiency and consistency.

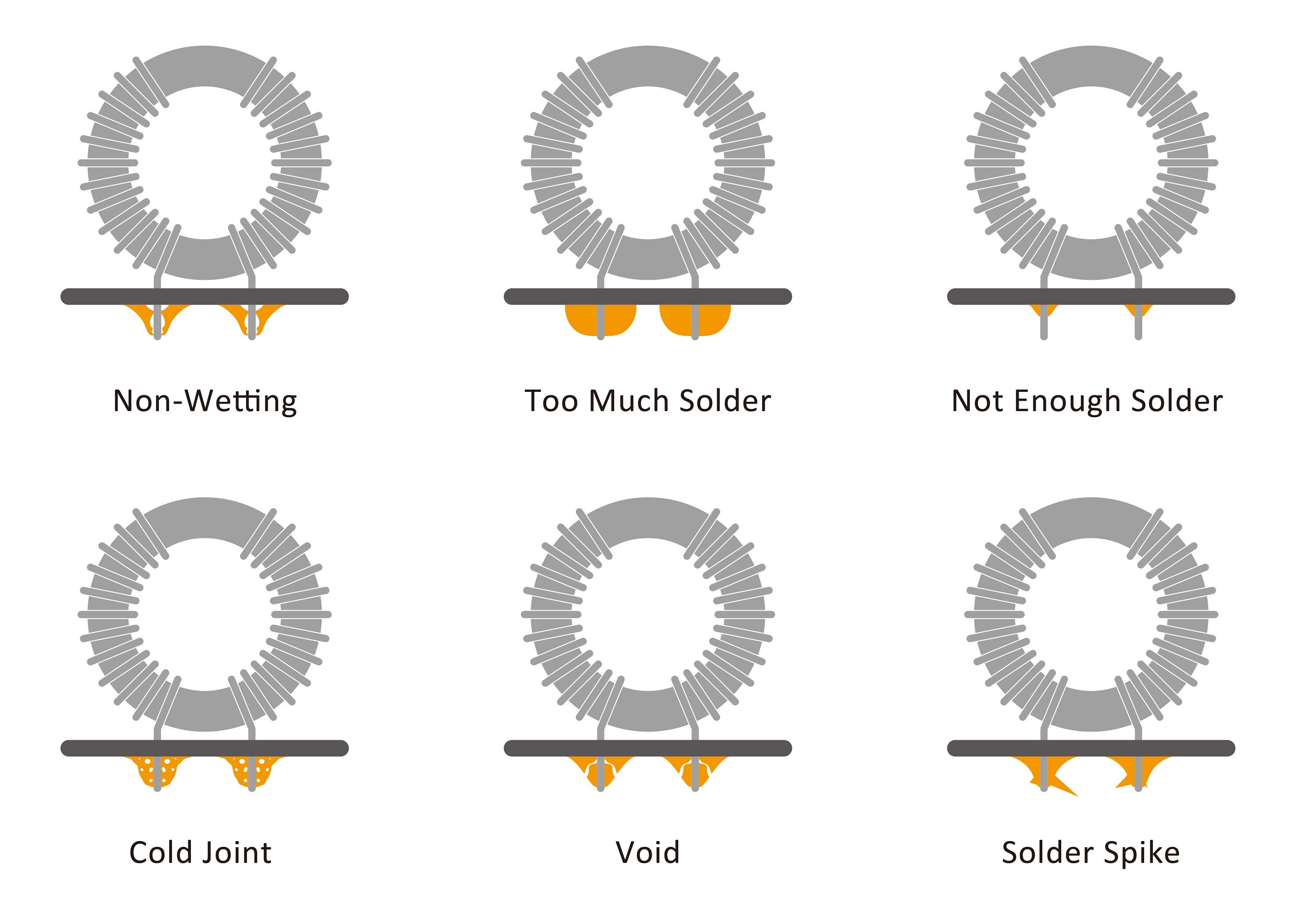

2、 The following conditions are considered non-compliant solder joints :

2-1. Insufficient Wetting / Cold Joint :

Appears soldered but lacks a proper connection. This may be due to contamination on the solder pad or pin, or insufficient heating time for the flux.

2-2. Short Circuit :

Occurs when excessive solder connects legs or components, resulting in a short circuit between legs. Another scenario involves improper handling by inspectors using pliers, bamboo sticks, etc., leading to inadvertent contact and short circuits between legs. This also includes short circuits caused by residual solder debris.

2-3. Cold Solder :

Cold solder refers to a situation where the solder fails to fully wet the soldering surface during the soldering process, resulting in uneven solder joints. This may be caused by surface contamination, incorrect soldering temperatures, or insufficient flux. Cold soldering can affect the strength and reliability of the solder joint.

2-4. Cracks :

Cracks in solder joints may be caused by thermal shock stress or other stresses. Cracks can weaken the strength of the solder joint and may potentially expand further during usage.

2-5. Burn hole :

Burn hole refers to the appearance of voids or holes in solder joints, often caused by excessively high soldering temperatures or improper soldering parameters. Burn holes can impact the mechanical strength and conductivity of the solder joint.

2-6. Solder Ball :

Solder ball refers to the small ball-like structures present in a solder joint, which may result from poor soldering techniques, uneven soldering materials, or other factors. Solder balls can lead to instability and reliability issues in the solder joint.

2-7. Insufficient Wettability :

If the solder joint fails to adequately wet the soldering surface, it may result in an insecure connection, affecting the strength and reliability of the solder joint.

2-8. Oxidation :

Oxidation is a common issue during the soldering process with lead-free solder, especially in high-temperature environments. Oxidation can lead to a decrease in the surface quality of the solder joint, impacting the quality of the connection.

3、 Possible Factors for Dull Solder Joints After Tinning

3-1. Oxidation :

If oxygen is present during the soldering process or during the cooling of the solder joint, the surface of the solder joint may oxidize, forming an oxide layer. This can result in a dull appearance on the surface of the solder joint. The risk of oxidation can be reduced by using nitrogen or other active gas, along with careful control of the soldering process.

3-2. Insufficient Soldering Temperature :

If the soldering temperature is insufficient, the solder may not fully melt and spread, leading to an uneven surface and a dull appearance. Ensure that the soldering temperature is adequate to ensure good wettability and soldering quality.

3-3. Residual Flux :

If flux is used and not thoroughly removed, the residual flux may form irregular deposits on the surface of the solder joint, causing the joint to appear dull.

3-4. Improper Material :

Using low-quality soldering materials may result in an uneven or dull surface of the solder joint. Ensure the use of high-quality soldering materials that comply with relevant standards and specifications.

3-5. Poor Solder Joint Shape :

The shape and structure of the solder joint can also influence light reflection, thereby affecting its appearance. Ensure that the solder joint has the correct shape and structure, avoiding irregular shapes or structures.

3-6. Insufficient Soldering Time :

If the soldering time is too short, the solder may not adequately diffuse, resulting in an uneven surface of the solder joint. Ensure sufficient soldering time for achieving a smooth solder joint.

Related articles :

• What is the difference between lead-free solder and leaded solder ?

• Welding - cause analysis and method of Solder Icicle solution

• 20 Tips for Soldering Inductor Components

GOTREND Technology Co., Ltd.

GOTREND Technology Co., Ltd.