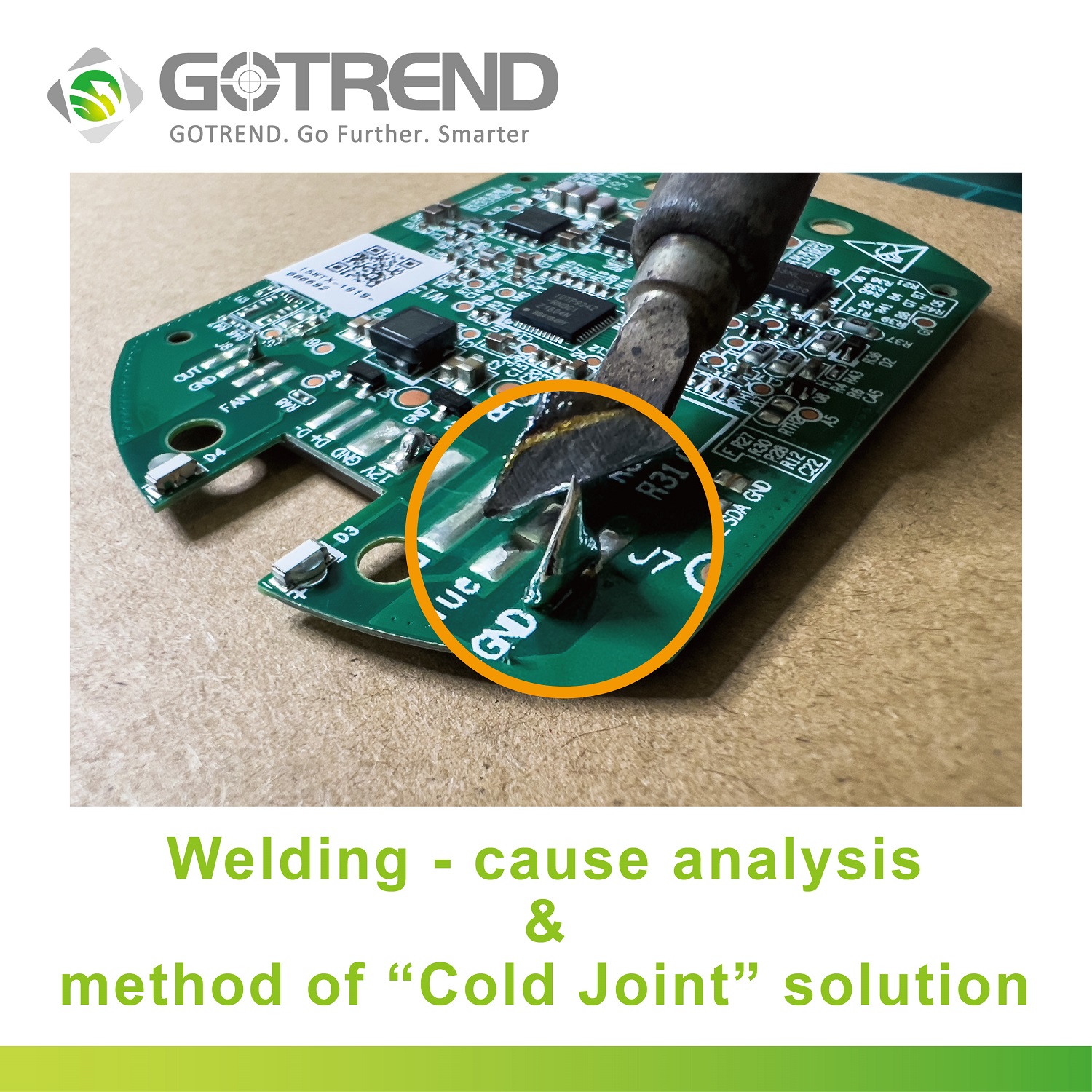

Welding - cause analysis and method of Solder Icicle solution

![]() 2023.4.12

2023.4.12

Articles

Articles

With solder wire soldering, it’s still a common process in the GOTREND inductor process, and the general production unit will encounter some problems in soldering, and there will be some problems in the use of products.

In the same way, there may be a problem in the wave soldering process, that is the phenomenon of tin beads or tin tips, why does it occur ?

In many cases, because there is moisture on the through hole of the PCB board, when welding, due to the moisture being heated into water vapor, Water vapor splashes the solder out of the solder bath, will produce irregular solder balls, which is also the same principle that we use solder wire solder will appear sharpening, so what to do in this case ?

Generally, the reasons why the “Solder Icicle” appears when the solder wire is soldered :

1. The temperature of tin is too low, and the optimal solder temperature isn’t reached.

2. The purity of tin isn’t enough, and there are many impurities.

3. Flux concentration isn’t enough.

4. The object leaves the tin too quickly.

5. The preheating time is insufficient or the preheating temperature is too low.

What should I do if "Solder Icicle" appears with solder wire?

First of all, it is necessary to understand that the solder joint isn’t plump is related to the tin content, purity and flux activity of the solder wire, and it isn’t easy to tin and has nothing to do with the tin content.

1、Related to the quality of the metal to be welded

Whether the metal is difficult to weld and the degree of oxidation on the surface of the material will affect the dispersion force and the "Solder Icicle" condition, usually need to choose different types of flux content for different metals of solder wire, In this way, it can effectively enhance the dispersion force during solder wire soldering, reduce the problem of pulling and so on.

2、It’s related to the wattage of the electric soldering iron

The temperature required for solder wire soldering with different tin content is different.

When using a low-wattage soldering iron and a low-tin content solder wire, the solder is in a semi-dissolved state due to insufficient temperature, and it is easy to present Solder Icicle. Therefore, it is necessary to select a suitable soldering iron for soldering.

3、It’s related to the active agent of the flux

The active agent with strong activity, the dispersion force is better, the dehydration can be relatively strong, and the electrical function is relatively stable.

Therefore, the use of solder wire with good flux activity can deal with Solder Icicle, but the flux with good activity brings problems such as smoke.

Related articles:

• What is the difference between copper wire and aluminum wire?

• What is the Q value of the inductor? How do I increase the Q value?

• What is an inductor?

GOTREND Technology Co.,Ltd

GOTREND Technology Co.,Ltd