Factors affecting the magnitude of the inductance value?

![]() 2022.9.14

2022.9.14

Articles

Articles

1、Overview of inductance

Inductance is a physical quantity that indicates the self-inductive capability of an inductive element. When the magnetic flux through a coil changes, an electromotive force is generated in the coil, which is an electromagnetic induction phenomenon. The resulting electromotive force is called induced electromotive force, and the magnitude of the electromotive force is proportional to the speed of the magnetic flux change and the number of coil turns.

• Inductance units: Henry (H), Millihenry (mH), Microhenry (μH), Nanohenry (nH)

• The conversion relationship is: 1H=〖10〗^3mH=〖10〗^6μH =〖10〗^9nH.

• Conversion : The n-th power of the value X10, such as〖10〗^3, that is, the third power nH of 10X10 is 10μH.

• The conversion relationship is: 1H=〖10〗^3mH=〖10〗^6μH =〖10〗^9nH.

• Conversion : The n-th power of the value X10, such as〖10〗^3, that is, the third power nH of 10X10 is 10μH.

2、Calculation of inductance

(1) Calculation formula for inductance of hollow coils

L= (0.01*D*N^2) / (L/D+0.44)

• Coil inductance L unit: uH

• Coil diameter D unit: cm

• Number of coils N unit: turns

• Coil length L unit: cm

• Coil diameter D unit: cm

• Number of coils N unit: turns

• Coil length L unit: cm

(2) Calculation formula of ring inductance

For the ring CORE, the following formula is available: (IRON)

L = AL *N ^ 2

• N = number of coil turns (number of turns) ; AL = induction coefficient

• For example: T50-52 material, the coil is 5 and a half turns, and its L value is T50-52(indicating that the OD is 0.5 inches), and its AL value is about 33nH

• Calculation: L= AL*N^2=33*(5.5)^2=998.25nH=1μH

(3) Empirical formula

L= (k*μ0*μs*N^2*S) / l

• μ0 is the vacuum permeability.

• μs is the relative permeability of the core inside the coil, and μs = 1 in the hollow coil.

• N^2 is the square of the number of coils.

• S is the cross-sectional area of the S coil in m^2.

• L is the length of the coil in m.

• k coefficient, depending on the ratio of the radius (R) of the coil to the length (l).

• The calculated inductance is measured in H.

• μs is the relative permeability of the core inside the coil, and μs = 1 in the hollow coil.

• N^2 is the square of the number of coils.

• S is the cross-sectional area of the S coil in m^2.

• L is the length of the coil in m.

• k coefficient, depending on the ratio of the radius (R) of the coil to the length (l).

• The calculated inductance is measured in H.

3、Factors influencing inductance value :

(1)The turns of the coil

From the calculation formula of the air core coil, it can be seen that the size of the inductance is proportional to the square of the number of coils, and the number of revolutions directly affects the value of the inductance, which is also one of the most important factors affecting the value of the inductance.

(2)Coil diameter & length

The larger the diameter and length of the coil, the larger the field area of the coil, the more magnetic lines will be induced by the coil, the greater the inductance will be, and the greater the inductance will be reflected in the inductance measured by the coil.

(3)The material of the iron core

With the diversification of the application of inductive coils, the inductance of the core coil has been far from meeting the needs of diversified applications, the mainstream inductive coils will increase the core material on the basis of the traditional core coil to increase the induction strength of the coil, so as to achieve the purpose of enhancing the inductive coil induction magnetic field, due to the development of the inductive industry, the application is more and more diversified, the material of the core also appears a variety of specifications, the core permeability from tens of thousands to tens of thousands, the types of materials also have hundreds of kinds, Therefore, the inductive coil with different core materials will directly affect the inductance of the inductor coil and the electrical properties such as current.

(In practical applications, it is necessary to consider the rated current, operating frequency, DC resistance, impedance, quality factors and other electrical parameters to select the appropriate magnetic material under the comprehensive consideration)

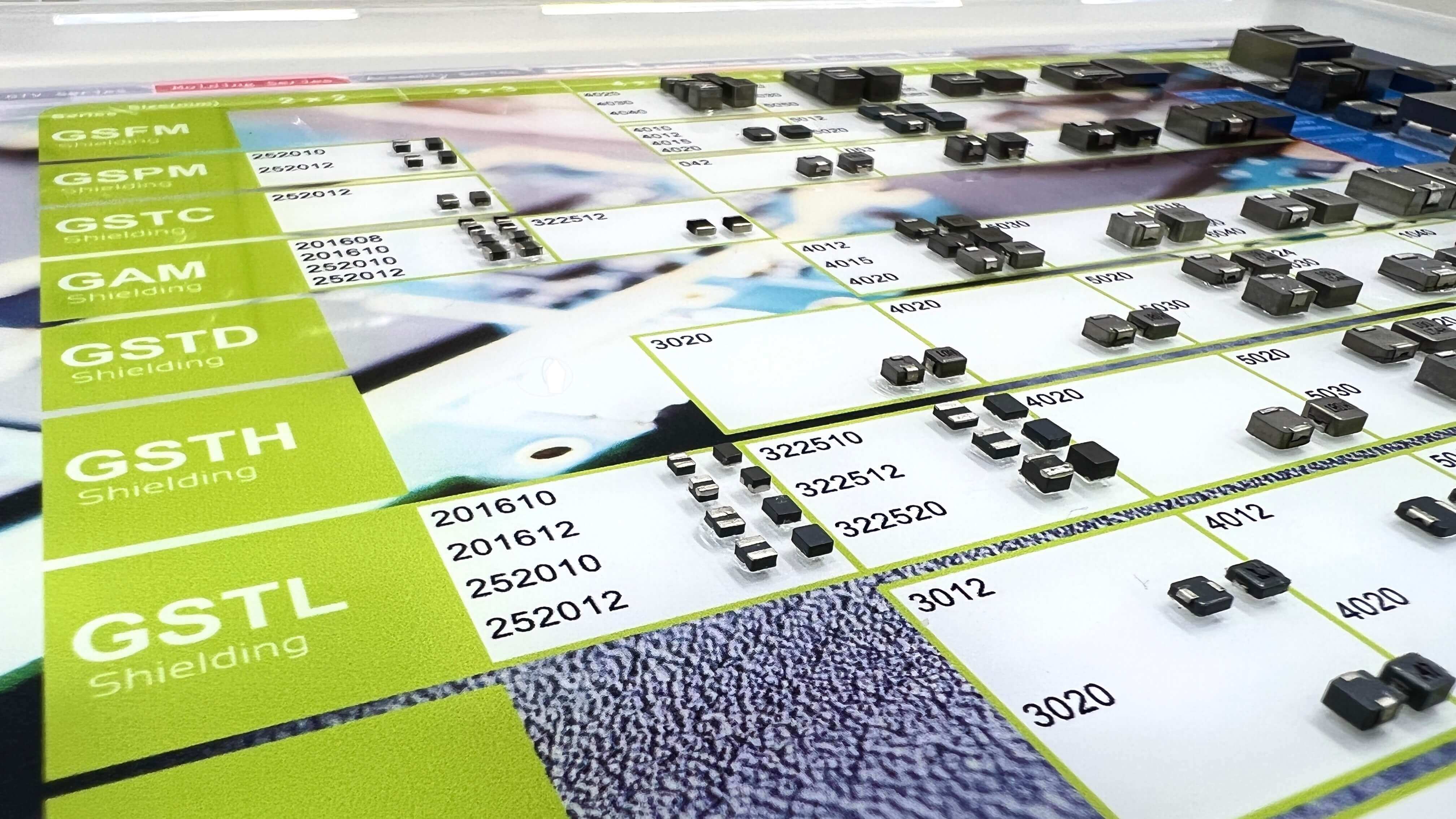

(4) Structure of the inductor (process)

As the three passive components of the electronic information industry, the inductor industry has undergone a difficult process from scratch.

Since the 1990s, the world's communication equipment, consumer electronics, computer industry, Internet technology application products, automotive electronics, set-top boxes and other industries have developed rapidly, and the manufacturing process of inductors has also undergone significant changes and improvements, from the traditional DIP structure, gradually to the development of SMT structure, and from the traditional manual assembly structure to the automation process. The direction of industry development has brought about the optimization of the inductance structure, the coil winding density has also been greatly improved, and due to the modification of the use environment, the inductance has also changed from the unshielded structure to the shielded structure, so different structures due to the different winding density of the inductor, whether there is a shielding cover will have an impact on the size of the inductance value.

4、Measurement Method & Notes:

(1)Pay attention to the working frequency of the inductor coil.

At low frequencies, inductor coils generally exhibit inductive characteristics, which are mainly used for energy storage and filtering (high frequency wave). However, at high frequencies, the inductive coil exhibits impedance characteristics, which plays a resistive role, and is accompanied by energy consumption and heat generation, and inductive effect is reduced. The high-frequency characteristics of different inductors are different.

(2) Attention must be paid to the environment in which the inductor coil is used:

The use of inductor coils should fully consider its working environment, first of all, pay attention to the temperature of the environment in which the product is located, humidity, and whether the surrounding electromagnetic interference signal source will affect the normal operation of the inductor coil.

(3) Pay attention to the Q value of the inductor coil :

Taking the I-type inductor coil as an example, the same inductance value, the magnetic material used is different, the final Q value will be different, and the appropriate magnetic material should be selected according to the actual Q value requirements of the inductor coil.

(4) Pay attention to the current loading of the inductor coil :

The inductor coil should be used within the rated current range of the design, and should not exceed the maximum carrying current, otherwise it is easy to cause the coil to burn out.

(5) Pay attention to the DCR value of the inductor coil :

The DCR value is the DC current value of the coil itself, the value of the DCR will affect the size of the inductor rated current, usually in the design of the inductance value to consider the coil's wire diameter.

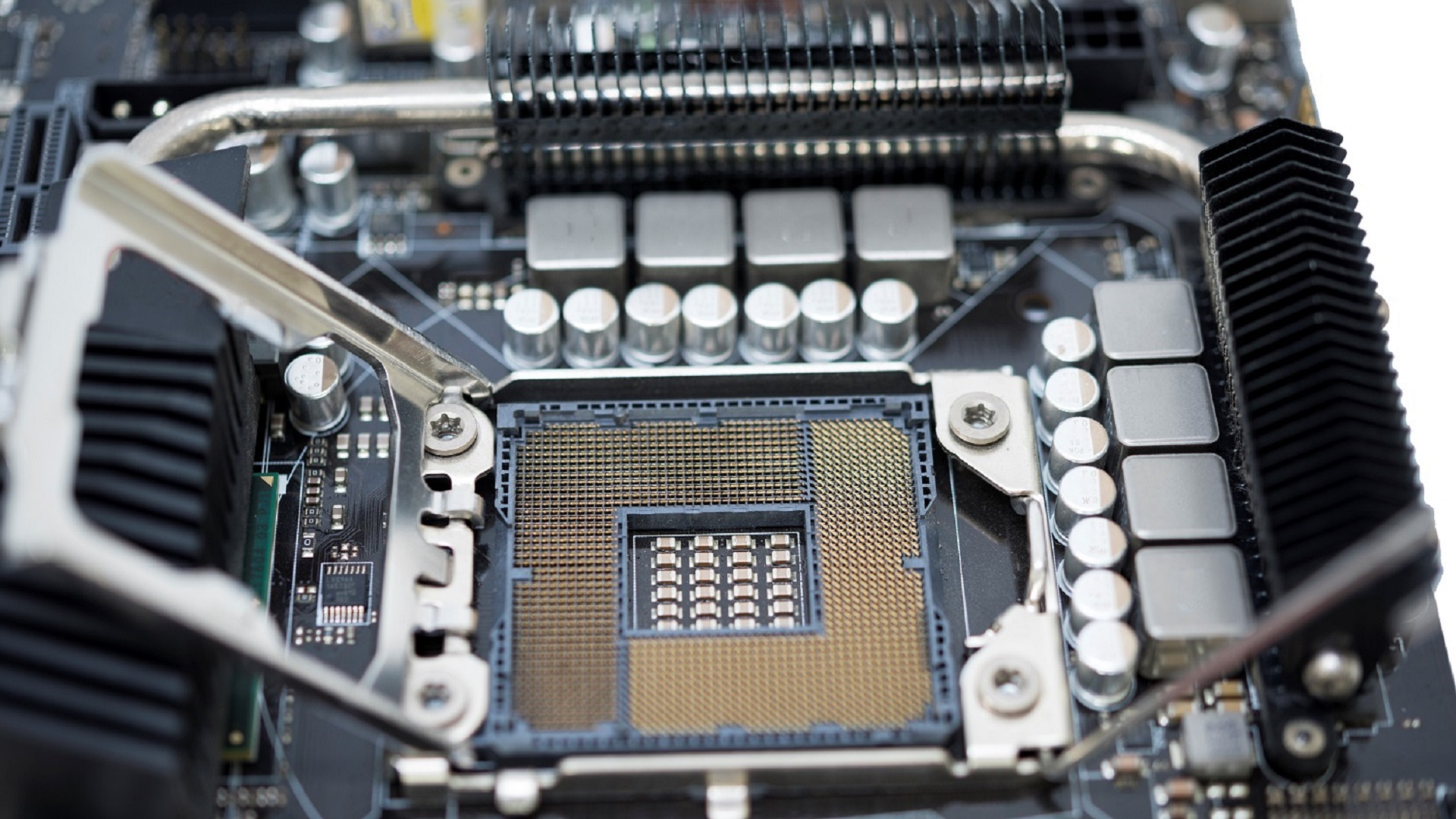

(6) Suitable inductor package size and appearance :

Although the corresponding performance parameters are reached, the inductor coil can already theoretically ensure that the inductor realizes the due use effect, but when manufacturing the finished product, it is also necessary to consider the position of the inductor coil in the PCB, and select the appropriate installation method, package size, and appearance to ensure product realization.

GOTREND Technology Co.,Ltd

GOTREND Technology Co.,Ltd