Automotive Chip Ferrite Bead & selection

![]() 2023.3.15

2023.3.15

Articles

Articles

1.Overview

In recent years, with the development of new energy vehicles and the continuous improvement of autonomous driving technology, more and more electronic devices have appeared in automobiles, and the demand for noise suppression components that transmit noise & radiated noise is increasing due to the increase in wireless specifications installed on these devices and the high speed of semiconductor operating frequencies.

The following describes the characteristics, main parameters, key electrical properties of magnetic beads, and the application necessity of high-reliability chip ferrite beads for automobiles.

2.What are the similarities and differences between beads and inductors?

The symbols of the bead and the inductor in the circuit are the same, but they are different devices, the bead unit is Ohm (Ω), and the unit of inductance is Heng (H).

The magnetic bead is composed of ferrite magnetic, the inductor is composed of a magnetic core and a coil, the magnetic bead converts the AC signal into heat energy, the inductor stores the AC and releases it slowly, so the inductor is energy storage, and the magnetic bead is an energy conversion (consumption) device.

We all know that EMI has two pathways, radiation and conduction, magnetic beads and inductors can solve EMC and EMI problems, but the focus is different.

▶ Magnetic beads :

Mainly solve the problem of radiation interference, signal lines multi-use magnetic beads, some high-frequency circuits such as RF, oscillation circuits, DDR SDRAM, etc. need to add magnetic beads to the power input part.

▶ Inductors mainly solve conducted interference problems, High-frequency inductors are mainly used for medium and low frequency filter circuits, RF matching, etc. Power inductors are mainly used in DC-DC circuits.

3. What are the main parameters of magnetic beads?

(1) Impedance【Z】:

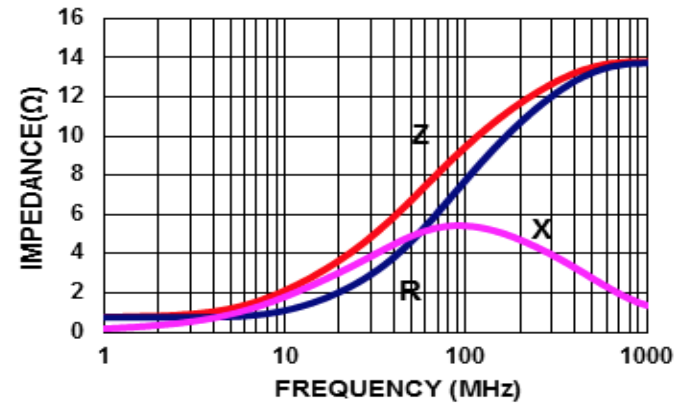

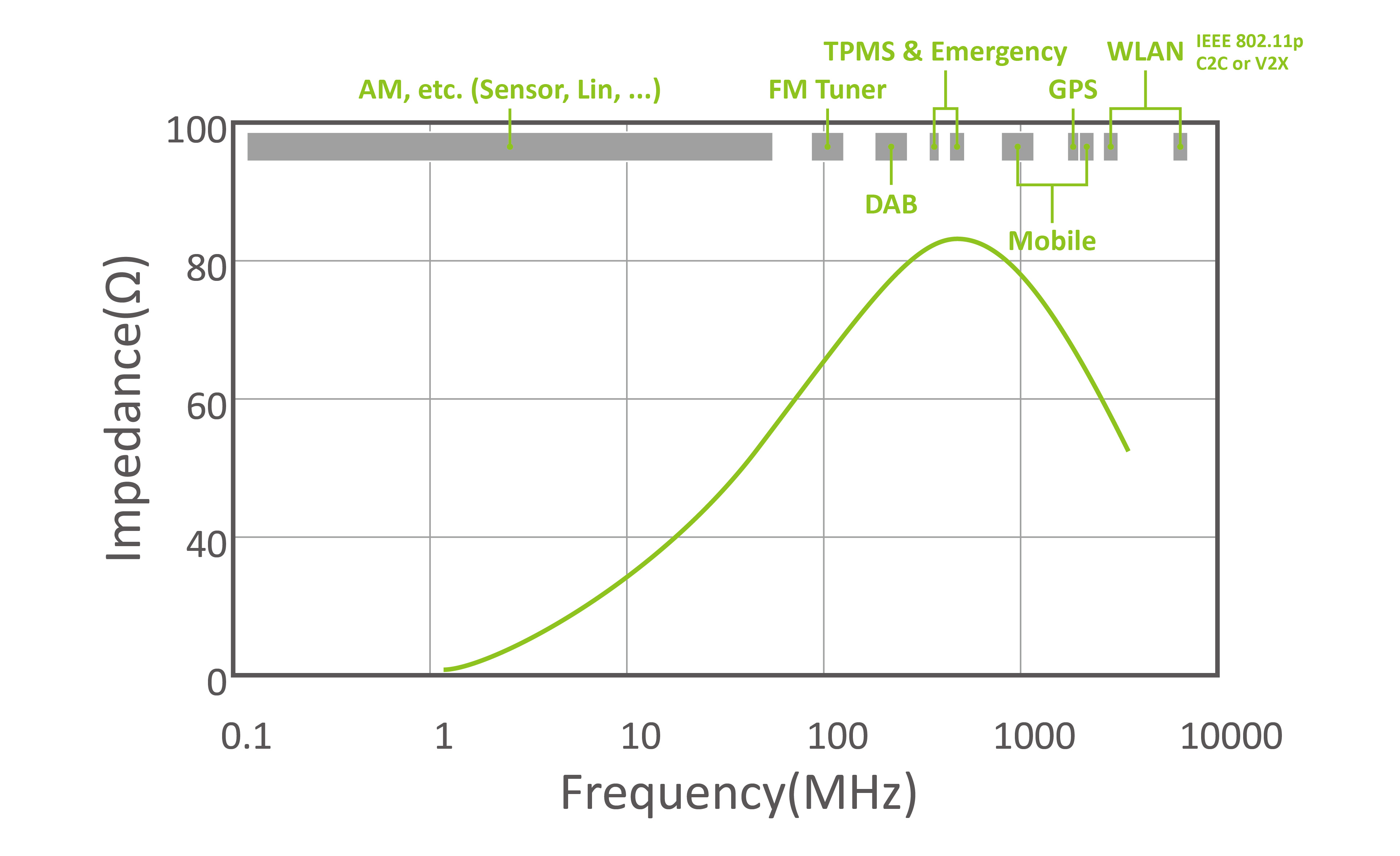

The industry is accustomed to the impedance of the bead determined by the impedance at 100MHz, so we often see 100R@100MHz in the SPEC. of the bead, which means that at the frequency of 100MHz, the impedance of the bead is 100R, the greater the impedance, the better the effect of suppressing noise, and some high-frequency beads give an impedance at the frequency of 1GHz,that means the bead is used for high-frequency noise suppressor. (GOTREND GBD-GF Series)

One thing to note is that looking at the figure above, at 100MHz, the impedance of the bead isn't the largest, so the model with the largest impedance near the frequency point can be selected according to the noise frequency point.

100MHz is only a standard in a sense, just a standard, I personally think that there is not much practical significance, because magnetic beads in practical applications, with the change of frequency, the impedance will change accordingly.

Therefore, there are very few cases of beads for single-point grounding, and it is necessary to evaluate the frequency range of noise in advance. You could have wide band usage (GOTREND GBD-GA Series) or narrow band usage (GOTREND GBD-GB Series).

▶ Specification Download

(2) DC resistance DCR :

Refers to the resistance value presented by the magnetic bead when the DC current passes through the bead, and the smaller DCR the better, and the smaller the attenuation of the useful signal.

(3) Rated Current :

Refers to the maximum current allowed when the bead works normally.

Traditional chip ferrite beads, generally referred to as "multilayer ferrite beads" are usually difficult to produce very low DC impedance conduction lines under this printing process, so the withstand current cannot be very large, and usually can only increase the withstand current with the enlargement of the length, width and high volume ( GOTREND GBD-GH Series ) ; Considering that current customers have more and more demand for EMC solution in the power supply circui, GOTREND has also launched GBC Series with a total of 3 sizes achieved low DCR & high SMT placement reliability and a maximum withstand current of tens of amperes, which will be the best noise suppressing solution in your industrial host design/server computer design/automotive electronics application design.

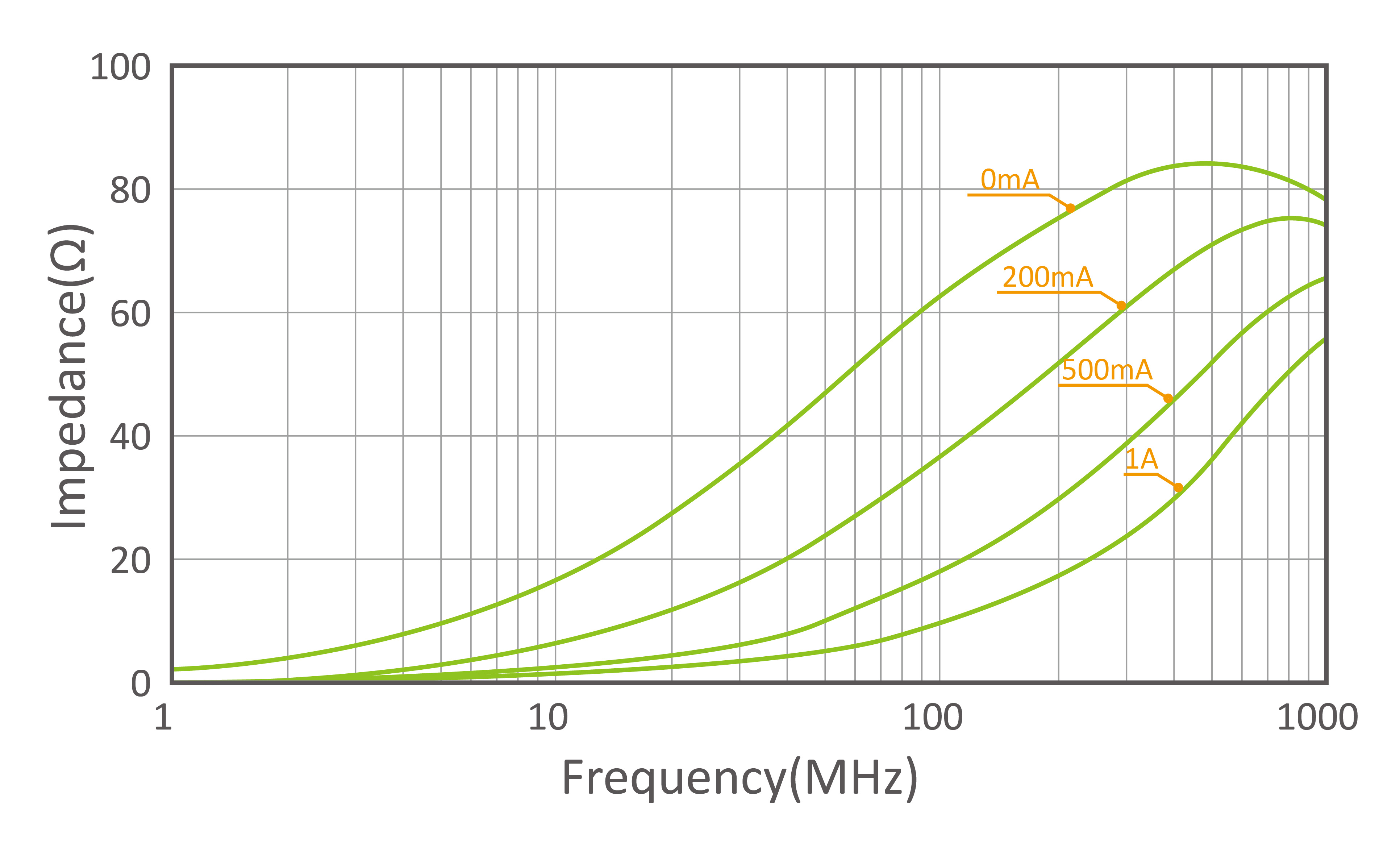

4. What are the DC overlap characteristics of magnetic beads?

We all know that when different DC voltages are added to the capacitor, the capacitance capacity will change, and the beads also have the same DC overlapping characteristics, and the chip ferrite bead is an inductor that uses ferrite. Therefore, when a large current is passed, special attention needs to be paid to the performance changes due to magnetic saturation.

( Figure.1 )

Therefore, when selecting, we must consider the two parameters of rated current and impedance.

5. Precautions for magnetic bead selection

(1) The frequency band for analyzing the frequency noise of useful signals and noise should be larger than the crossover frequency, so that the magnetic beads absorb noise instead of reflecting noise; The frequency of the signal is less than the crossover frequency, preventing the signal from being attenuated.

(2) Consider the size of the DCR in the DC circuit, to prevent the DCR from being too large, resulting in signal attenuation, such as a 5V 500mA power supply, when passing through a DCR=1R bead, the voltage will be attenuated by 500mA*1R=0.5V.

In general, the greater the AC impedance, the better the filtering noise, but the DCR will also be large, and there is attenuation of the useful signal, so this is a trade-off process.

(3) Considering the size of the rated current, don’t blindly choose a magnetic bead with a low rated current in order to save costs, considering the DC overlap characteristics, as the current increases, the impedance decreases, and the noise absorption performance will also decrease. For example, if a circuit operates below 300mA most of the time, up to 400mA, but rarely, you can choose a bead with a rated current of 400mA.

6. The necessity of ferrite beads for vehicles

Here are 2 reasons why ferrite beads must be used on automotive devices:

(1) Complies with automotive noise suppression specifications

Compared with the general equipment specification (CISPR22), the stricter specification (CISPR25) for automotive equipment can be applied in more cases, and it is necessary to recognize the countermeasures within the specified frequency band.

This frequency band includes the 150kHz AM wireless band that has been used for a long time, and the 6GHz band for car audio entertainment equipment equipped with multiple GHz band wireless.

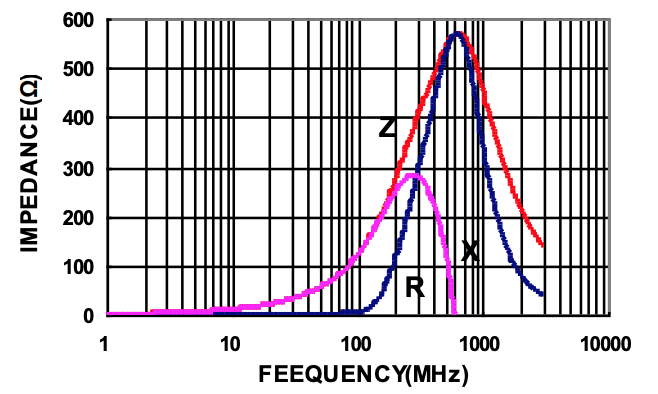

Ferrite beads have the noise suppression characteristics of the FM tuner band ~ GHz band with relatively high noise suppression difficulty. (Figure2)

Figure (2) The noise suppression characteristics of frequency bands and

representative ferrite beads required by noise suppression specifications for automotive equipment

(2) Improved noise tolerance of the sensor

With the development of intelligent car technology, unmanned & autonomous driving gradually turned from science fiction to reality, one of the characteristics of the development of automotive autonomous driving technology is that more and more parts of the car adopt electronic control, and collect various information through the built-in sensors of the car to feed back to the "brain" of the car Electronic control unit (ECU), the temperature, flow, pressure, etc. detected by various sensors are mastered, and the engine operating state and exhaust state are controlled and slightly adjusted.

Vehicles incorporating advanced autonomous driving technology can grasp the external environment such as pedestrians and road conditions through various sensors, and feed back to the ECU to control the vehicle's steering wheel, brakes, accelerator, etc. Therefore, the important perception ability of the sensor needs to avoid deterioration caused by noise as much as possible, and the sensor with built-in ferrite beads can effectively improve the anti-noise interference.

GOTREND's chip ferrite beads offer a small-size, low-cost leading-edge lineup of full-size EMC (Electro Magnetic Compatibility) noise suppression components.

It is possible to easily eliminate noise information in various frequency bands, especially in the high-frequency band domain exceeding 100 MHz, and realize the electrical properties of high impedance and high current through a unique material design, and effectively play the effect of EMC noise suppression.

2-1 : Demand for high temperature resistant ferrite beads

Due to the influence of the greenhouse effect, the realization of "carbon neutrality" has been the common vision of human beings around the world, the automotive industry to new energy, lightweight development has gradually become a consensus, the lightweight of vehicle components for higher than 125 °C high temperature resistance ferrite beads are also getting higher and higher.

(1) Install an electronic control unit (ECU) in the traditional engine chassis to monitor the fuel consumption of the car at any time and reduce the emission of carbon dioxide, and the sensor in the high temperature environment in the engine chassis requires a high-temperature resistant and high-reliability 125°C high-temperature ferrite bead.

(2) The miniaturization of electronic control units (ECU) requires the installation of ferrite beads near heat-generating components (semiconductors), and because heat is easy to accumulate and form high temperatures, ordinary magnetic beads cannot adapt to high-temperature environments.

(3) The sensor in the engine system and exhaust system environment needs to be in a high temperature state, and it must also withstand high temperature when ferrite beads are built into the sensor.

Global warming and the greenhouse effect are causing the global temperature to rise, and the requirement for high-temperature resistance of in-vehicle electronic components is becoming essential.

GOTREND's 【Automotive Chip Ferrite Beads】 comply with AEC-Q200 standards, and through new materials and unique technologies, we have achieved high reliability that can withstand environments such as engine chassis, and meet the needs of all automotive equipment that guarantee temperature.

(3) Introduction of GOTREND Multilayer Chip Ferrite Beads

GOTREND's lineup of 【Multilayer Chip Ferrite Beads】 :

▶ Specification Download

|

Product |

GOTREND PN. |

Material |

Number of items |

Impedance |

Rated current |

DC |

|

GA : Wide Band |

GBD060303PGA-SERIES | Ni-Sn-Ferrite Body | 8 | 33 to 1000 Ω | 160 to 400 mA | 0.3 to 1.15 Ω |

| GBD100505PGA-SERIES | Ni-Sn-Ferrite Body | 17 | 10 to 1800 Ω | 100 to 1000 mA | 0.05 to 1.4 Ω | |

| GBD160808PGA-SERIES | Ni-Sn-Ferrite Body | 8 | 60 to 2000 Ω | 200 to 300 mA | 0.1 to 0.75 Ω | |

| GBD201209PGA-SERIES | Ni-Sn-Ferrite Body | 4 | 17 to 2200 Ω | 200 to 600 mA | 0.1 to 0.6 Ω | |

| GBD321611PGA-SERIES | Ni-Sn-Ferrite Body | 3 | 500 to2000 Ω | 400 to 1000 mA | 0.2 to 0.35 Ω | |

| GBD321616PGA-SERIES | Ni-Sn-Ferrite Body | 3 | 25 to 70 Ω | 500 mA | 0.1 to 0.2 Ω | |

| GBD322513PGA-SERIES | Ni-Sn-Ferrite Body | 3 | 32 to 90 Ω | 500 mA | 0.2 Ω | |

| GBD451616PGA-SERIES | Ni-Sn-Ferrite Body | 6 | 50 to 170 Ω | 500 to 600 mA | 0.2 to 0.3 Ω | |

| GBD453215PGA-SERIES | Ni-Sn-Ferrite Body | 2 | 70 to 120 Ω | 500 mA | 0.3 Ω | |

|

GB : Narrow Band |

GBD100505PGB-SERIES | Ni-Sn-Ferrite Body | 5 | 60 to 120 Ω | 50 to 300 mA | 0.10 to 0.80 Ω |

| GBD160808PGB-SERIES | Ni-Sn-Ferrite Body | 21 | 6 to 2200 Ω | 50 to 500 mA | 0.05 to 1.5 Ω | |

| GBD201209PGB-SERIES | Ni-Sn-Ferrite Body | 25 | 6 to 2700 Ω | 100 to 800 mA | 0.07 to 0.85 Ω | |

| GBD321611PGB-SERIES | Ni-Sn-Ferrite Body | 14 | 19 to 1500 Ω | 150 to 600 mA | 0.2 to 1.2 Ω | |

| GH : High-Current | GBD060303PGH-SERIES | Ni-Sn-Ferrite Body | 8 | 10 to 600 Ω | 200 to 1000 mA | 0.05 to 1.1 Ω |

| GBD100505PGH-SERIES | Ni-Sn-Ferrite Body | 14 | 20 to 1800Ω | 250 to 4000 mA | 0.03 to 0.8 Ω | |

| GBD160806PGH-SERIES | Ni-Sn-Ferrite Body | 2 | 26 to 30 Ω | 6000 mA | 0.01 Ω | |

| GBD160808PGH-SERIES | Ni-Sn-Ferrite Body | 23 | 10 to 2200 Ω | 200 to 5000 mA | 0.02 to 0.75 Ω | |

| GBD201209PGH-SERIES | Ni-Sn-Ferrite Body | 25 | 10 to 2000 Ω | 500 to 4000 mA | 0.03 to 0.5 Ω | |

| GBD321611PGH-SERIES | Ni-Sn-Ferrite Body | 18 | 19 to 1500 Ω | 800 to 6000 mA | 0.015 to 0.7 Ω | |

| GBD322513PGH-SERIES | Ni-Sn-Ferrite Body | 2 | 60 to 90 Ω | 3000 to 4000 mA | 0.025 Ω | |

| GBD451616PGH-SERIES | Ni-Sn-Ferrite Body | 9 | 60 to 1000 Ω | 1500 to 3000 mA | 0.04 to 0.09 Ω | |

| GBD453215PGH-SERIES | Ni-Sn-Ferrite Body | 7 | 80 to 1300 Ω | 3000 to 9000 mA | 0.004 to 0.04 Ω | |

| GBD565032PGH-SERIES | Ni-Sn-Ferrite Body | 2 | 270 to 400 Ω | 4000 to 4500 mA | 0.03 to 0.035 Ω | |

| GBD565036PGH-SERIES | Ni-Sn-Ferrite Body | 2 | 600 to 800 Ω | 4000 to 8000 mA | 0.01 to 0.02 Ω | |

|

GF : High-Frequency

|

GBD100505PGF-SERIES | Ni-Sn-Ferrite Body | 7 | 200 to 1000 Ω | 100 to 500 mA | 0.70 to 1.60 Ω |

| GBD160808PGF-SERIES | Ni-Sn-Ferrite Body | 9 | 120 to 1200 Ω | 50 to 300 mA | 0.25 to 1.50 Ω | |

| GH : High-Current F: Material Code(Silver) |

GBD100505PGHF-SERIES | Ni-Sn-Silver-Ferrite Body | 8 | 10 to 600 Ω | 1000 to 4000 mA | 0.018 to 0.2 Ω |

| GBD160808PGHF-SERIES | Ni-Sn-Silver-Ferrite Body | 11 | 30 to1000 Ω | 1500 to 5000 mA | 0.01 to 0.15 Ω | |

| GBD201209PGHF-SERIES | Ni-Sn-Silver-Ferrite Body | 8 | 30 to 1000 Ω | 1600 to 8500 mA | 0.004 to 0.12 Ω | |

| GBD321611PGHF-SERIES | Ni-Sn-Silver-Ferrite Body | 8 | 30 to 1000 Ω | 2000 to 11000 mA | 0.0025 to 0.075 |

If you are interested in our products, please Contact Us.

GOTREND Technology Co.,Ltd

GOTREND Technology Co.,Ltd