TLVR Inductor【GTLVR Series】Ultra-Low DCR Ultra-Large Withstand Current Server-Grade Twin E-Core 1:1 TLVR Coupled Inductors

![]() 2023.3.31

2023.3.31

New Products

New Products

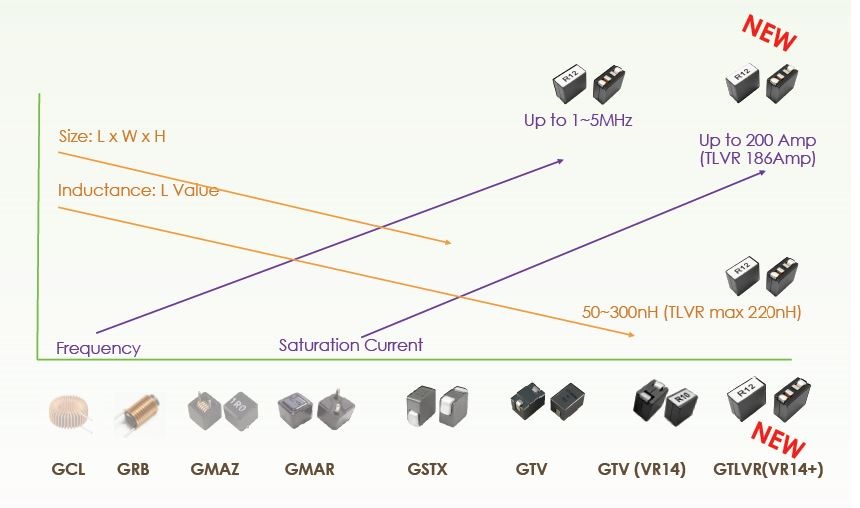

In traditional high-power CPU / GPU server products, the specification of VRM has reached version VR14, which defines discrete inductors ( Usually using gap core inductors, also known as gap Bead Core inductors, such as the GOTREND High Power GTV Series , designed for components like GPU CPU Vcore ). However, with increasing operating frequencies, lower inductance, Although it brings the ability to carry large power dissipation, the greater the ripple current and inductive coupling coefficient, more output capacitors are required , occupying more PCB space. These are the concerns of developers and also the bottlenecks for server performance and stability.

TLVR is a new structure of coupled inductors that solves the disadvantages of discrete inductors through a 1:1 transformer design and a simpler structure, while bringing more performance and cost competitiveness.

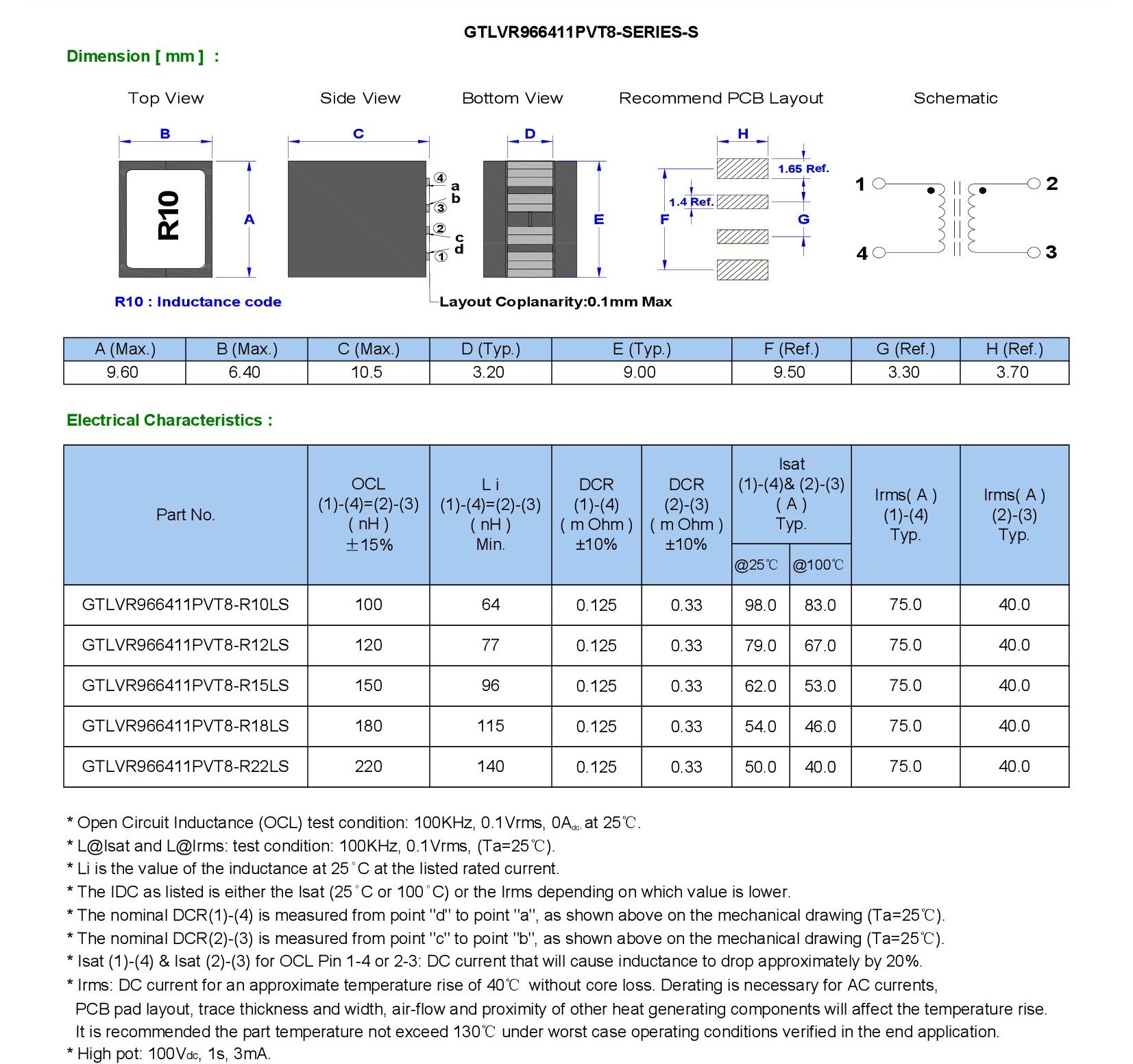

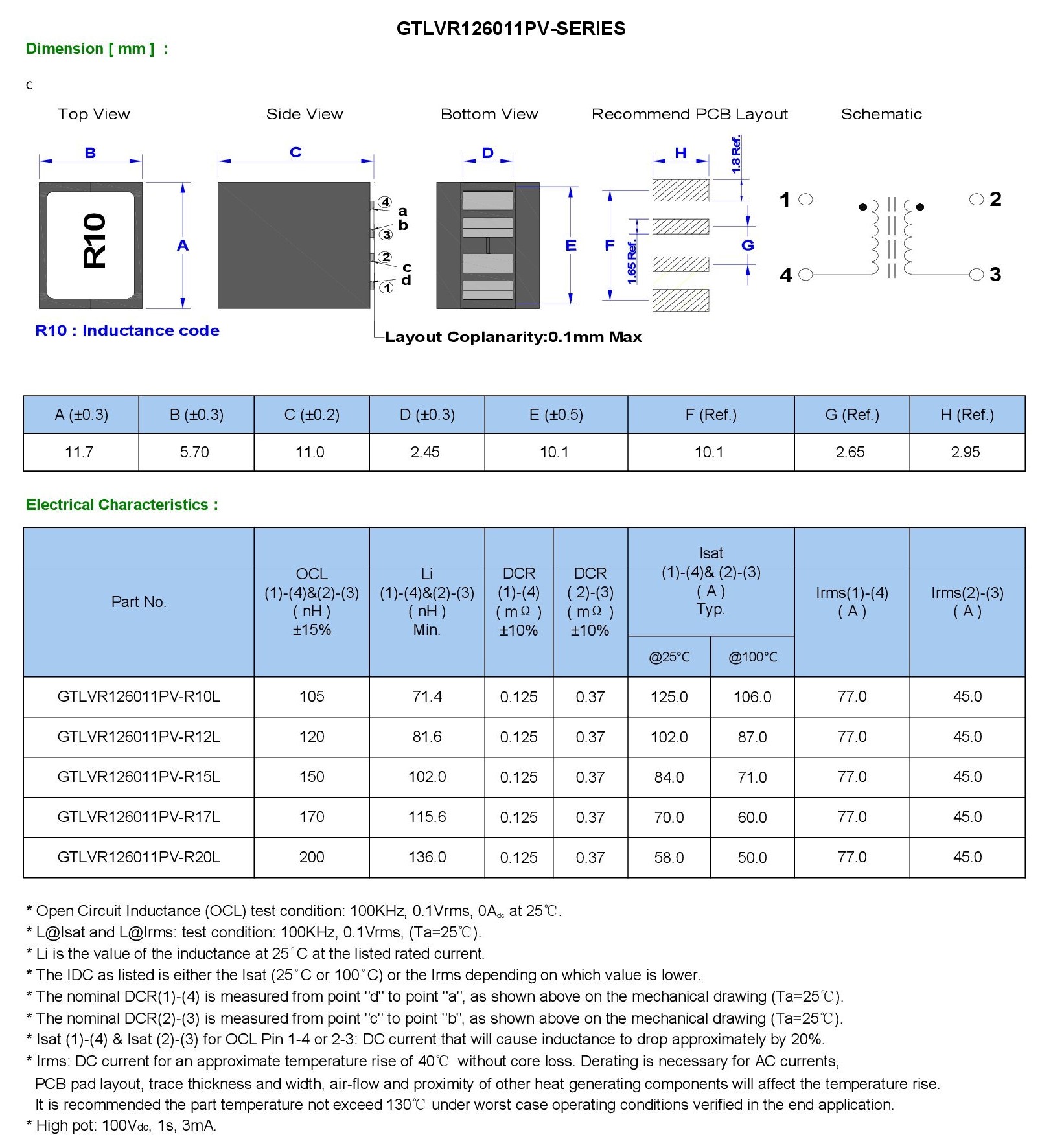

GOTREND Technology has launched the GTLVR966411PVT8 & GTLVR126011PV series of TLVR-coupled inductors with larger current resistance, stronger body, and excellent EMI performance, allowing you to apply them to products that require high reliability at a low cost, whether it's industrial computers, 5G base stations, servers, and more. They are your best choice!

TLVR is a new structure of coupled inductors that solves the disadvantages of discrete inductors through a 1:1 transformer design and a simpler structure, while bringing more performance and cost competitiveness.

GOTREND Technology has launched the GTLVR966411PVT8 & GTLVR126011PV series of TLVR-coupled inductors with larger current resistance, stronger body, and excellent EMI performance, allowing you to apply them to products that require high reliability at a low cost, whether it's industrial computers, 5G base stations, servers, and more. They are your best choice!

.jpg)

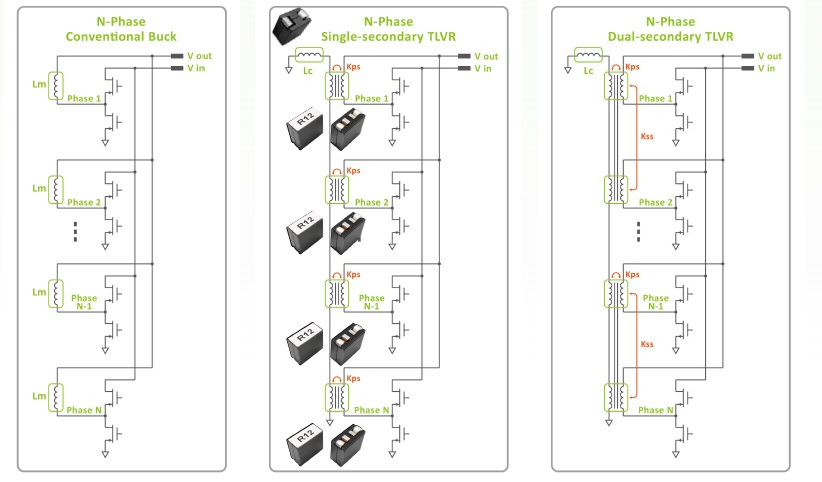

Server Power Inductor Evolution VR -> TLVR

Feature :

• 1:1 coupled inductor

• High operating frequency : up to 5MHz

• Small size : 9x6x10mm and 11x5x11mm

• Low DCR : 0.125/0.33 and 0.125/0.37 mohm

• High Isat-Irms : 98A-75A and 125A-77A

• Strong body with air gap characteristics

• Low copper resistance : direct pin terminals

• 5 L values : design to work with PMIC

• Hazardous substance : complies with RoHS

• Directive 2002/95/EC

• 1:1 coupled inductor

• High operating frequency : up to 5MHz

• Small size : 9x6x10mm and 11x5x11mm

• Low DCR : 0.125/0.33 and 0.125/0.37 mohm

• High Isat-Irms : 98A-75A and 125A-77A

• Strong body with air gap characteristics

• Low copper resistance : direct pin terminals

• 5 L values : design to work with PMIC

• Hazardous substance : complies with RoHS

• Directive 2002/95/EC

Advantage :

Traditional VR architecture multiphase (N Phase) power supplies use air-gap, high-current discrete inductors ( GOTREND GTV Series ) for many years in high power consumption.

The CPU/GPU server plays a great role in high conversion efficiency switching power supply in addition

to amplifier and voltage regulation,and its advantages and disadvantages are as follows :

With multi-phase power architecture (N Phase) shunting, the current demand at higher power can be achieved, but with the introduction of newer VRM versions, the number of power phases continues to increase. The switching frequency continues to rise, and at the same time a smaller inductor must be used to match the storage and discharge energy, although it seems to bring the benefit of carrying more current. But it also inevitably brings the following disadvantages.

Disadvantages :

The more phases, the more PCB space is occupied, and the smaller the inductance value used, which affects the Transient Response. Therefore, more output capacitors are required at the same time to offset the coupling effect and the more pronounced ripple current under dense inductance arrangement.

This is used to improve transient response to avoid too much reduction in conversion efficiency and to avoid the use of more output capacitors that can lead to a larger PCB footprint. And also disadvantages of procurement costs.

Application :

• PMIC multiphase voltage regulators

• New architecture Voltage Regulator Modules (TLVR)

• PC、Server、IPC、VRM and EVRD

• Data networks and storage systems

• Graphics cards, Battery power systems and PMIC control

• Point-of-load modules (POL)

• DCR sensing circuits

✏ Technical FAQ :

Q1: What are the advantages of coupled inductors over conventional discrete inductors?

A1 : Coupled inductors are commonly used in multiphase power supply topologies, taking advantage of their phase-to-phase magnetic coupling current ripple cancellation technology. With ordinary discrete inductors, current ripple can generally only be counteracted at the output of a multiphase buck converter. When the coupled inductor is magnetically coupled, the current ripple cancellation acts on all circuit components, MOSFETs, and inductor coils. All phase switching operations affect only the single phase, reducing the amplitude of current ripple and doubling the frequency. RMS with reduced current waveforms can help improve power conversion efficiency, or reduce magnetic components for a faster transient response, which in turn reduces output capacitance requirements

Q2: How does coupled inductance compare to conventional discrete inductor design?

A2 :

1、If the initial design of the original discrete inductor is reasonable and the current ripple is acceptable, the same current ripple can be obtained with a lower inductance when replacing the coupled inductor. Under such conditions, a coupled inductor of 50~100nH can provide the same current ripple effect as a 210nH

discrete inductor.

2、The coupling inductor is designed to be negatively coupled, and when the currents of each phase are equal, the mutual inductance magnetic flux from all coils cancels each other.

3、The coupling inductor size is smaller than traditional discrete solutions. At the same time, the current efficiency under fast transient response conditions is improved, and the inductance can be increased by (LC) compensation inductance, so as to achieve the benefits of reducing output capacitance and cost reduction

(ps: may vary according to individual customer design and materials)

Q3: In the initial evaluation of the solution, if the acceptance of terminal brand customers is uncertain, can there be a more flexible and secure co-layout sharing solution?

A3 : Yes,GOTREND GTV966610P can be co-layout with GTLVR966411.

Application circuit diagram :

Advance Technical Issue : (Resource from: Renesas Semi & MACNICA)

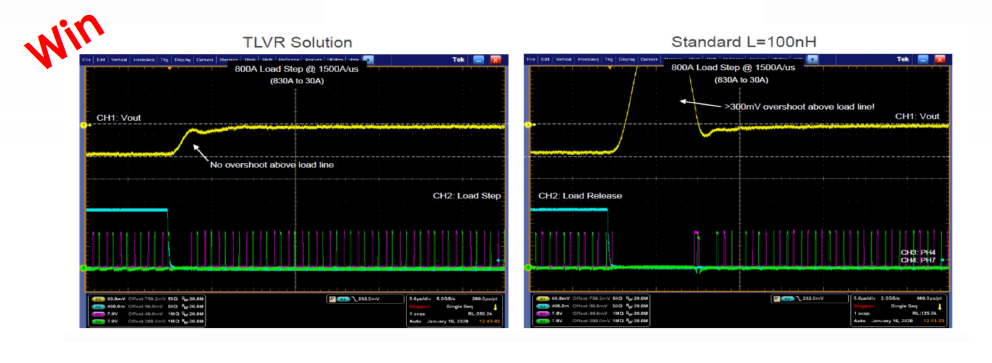

Test conditions :

VIN : 12V ,VOUT : 0.75V ,LL : 0.1mΩ,FW : 600kHz ,16PH : ISL99390 (Renesas)

Traditional inductor : 100nH ; TLVR inductance : 150nH and Lc =70nH.

Refer to the waveform above,using the same board and the same output capacitance,we verify the conventional and TLVR inductors.

Under the influence of transient load fluctuations,the blue load current waveform drops from 830 amps to 30 amperes.

It is found that the yellow output voltage waveform will vary greatly in different inductors.

TLVR inductor can effectively suppress voltage changes caused by load fluctuations,while traditional inductor voltage changes are very drastic.

If the conventional type wants to suppress the output voltage waveform change,the output terminal capacitor needs to add a lot of additional capacitors to suppress such output voltage waveform change.

Therefore,the use of TLVR inductor can't only save the number of capacitors at the output,but also greatly improve the space utilization.

But these still depend on whether the core power chip makes support related application.

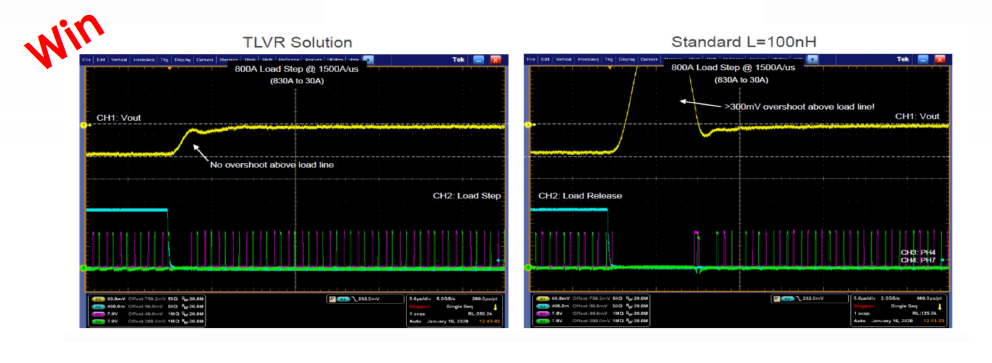

VIN : 12V ,VOUT : 0.75V ,LL : 0.1mΩ,FW : 600kHz ,16PH : ISL99390 (Renesas)

Traditional inductor : 100nH ; TLVR inductance : 150nH and Lc =70nH.

Refer to the waveform above,using the same board and the same output capacitance,we verify the conventional and TLVR inductors.

Under the influence of transient load fluctuations,the blue load current waveform drops from 830 amps to 30 amperes.

It is found that the yellow output voltage waveform will vary greatly in different inductors.

TLVR inductor can effectively suppress voltage changes caused by load fluctuations,while traditional inductor voltage changes are very drastic.

If the conventional type wants to suppress the output voltage waveform change,the output terminal capacitor needs to add a lot of additional capacitors to suppress such output voltage waveform change.

Therefore,the use of TLVR inductor can't only save the number of capacitors at the output,but also greatly improve the space utilization.

But these still depend on whether the core power chip makes support related application.

Comparison of Traditional VR Separated Inductor VS. TLVR Inductor Dynamic Loading Ratio

References Resource :

1. Fast multi-phase trans-inductor voltage regulator,Digital Commons,https://reurl.cc/VRGVDQ

2. TLVR High voltage considerations,Alexandr Ikriannikov,https://reurl.cc/YdMzeX

3. Renesas presentation

- Couple Inductor and TLVR

- Renesas TLVR Design Equations

1. Fast multi-phase trans-inductor voltage regulator,Digital Commons,https://reurl.cc/VRGVDQ

2. TLVR High voltage considerations,Alexandr Ikriannikov,https://reurl.cc/YdMzeX

3. Renesas presentation

- Couple Inductor and TLVR

- Renesas TLVR Design Equations

Product use environment :

1. Storage temperature range (components): -40°C to +125°C

2. Operating temperature range: -40°C to +125°C (ambient temperature + self-temperature rise)

3. Solder reflow temperature: according to J-STD-020 (latest version)

Packaging Specifications : 400pcs / 13” Tape Reel

1. Storage temperature range (components): -40°C to +125°C

2. Operating temperature range: -40°C to +125°C (ambient temperature + self-temperature rise)

3. Solder reflow temperature: according to J-STD-020 (latest version)

Packaging Specifications : 400pcs / 13” Tape Reel

Product use environment :

1. Storage temperature range (components): -40°C to +125°C

2. Operating temperature range: -40°C to +125°C (ambient temperature + self-temperature rise)

3. Solder reflow temperature: according to J-STD-020 (latest version)

Packaging Specifications : 400pcs / 13” Tape Reel

Related articles :

• Automotive Chip Ferrite Bead & selection

• What is an inductor?

• 【GPOE Series】New Power over Ethernet

New Products

New Products