Design and Application of Common Mode Chokes

![]() 2025.1.8

2025.1.8

Articles

Articles

1.The Function of Common Mode Chokes

A Common Mode Choke is an electromagnetic component used to suppress common mode interference.

Its main functions include :

• Suppressing Common Mode Interference : A common mode inductor effectively suppresses common mode interference, which occurs when interference signals appear simultaneously on two or more conductors in a circuit. This type of interference is typically caused by external electromagnetic fields, such as noise on power or signal lines.

• Improving Signal Integrity : By reducing common mode interference, the common mode inductor helps improve signal integrity, reducing signal distortion and enhancing communication quality and data transmission reliability.

• Protecting Sensitive Circuits : In electronic devices, common mode inductors protect sensitive analog and digital circuits from common mode interference, preventing performance degradation or equipment failure.

• Reducing Electromagnetic Interference (EMI) : Common mode inductors reduce the electromagnetic interference (EMI) emitted by devices, helping meet electromagnetic compatibility (EMC) requirements and passing various EMI testing.

• Power Line Filtering : In power circuits, common mode inductors are commonly used to filter high-frequency noise on power lines, improving power quality and reducing interference with other equipment.

• Signal Line Filtering : In signal lines, common mode inductors filter high-frequency interference, ensuring clear signal transmission.

• Differentiating Differential and Common Mode Interference : Common mode inductors provide high impedance to common mode interference while offering low impedance to differential mode signals (signals with opposite phases on two conductors). This enables the separation of common mode and differential signals, suppressing only the common mode interference.

• Enhancing Equipment Safety : By reducing electromagnetic interference, common mode inductors help improve equipment safety and reduce the risk of fire caused by EMI.

• Compliance with Regulatory Standards : In certain industries, such as healthcare, aerospace, and communications, devices must comply with specific electromagnetic compatibility standards. Common mode inductors are key components in achieving these standards.

Common mode inductors are often used in conjunction with differential mode inductors (chokes) to provide a comprehensive electromagnetic interference suppression solution. Through proper design and selection, common mode inductors can effectively enhance the electromagnetic compatibility and performance of electronic devices.

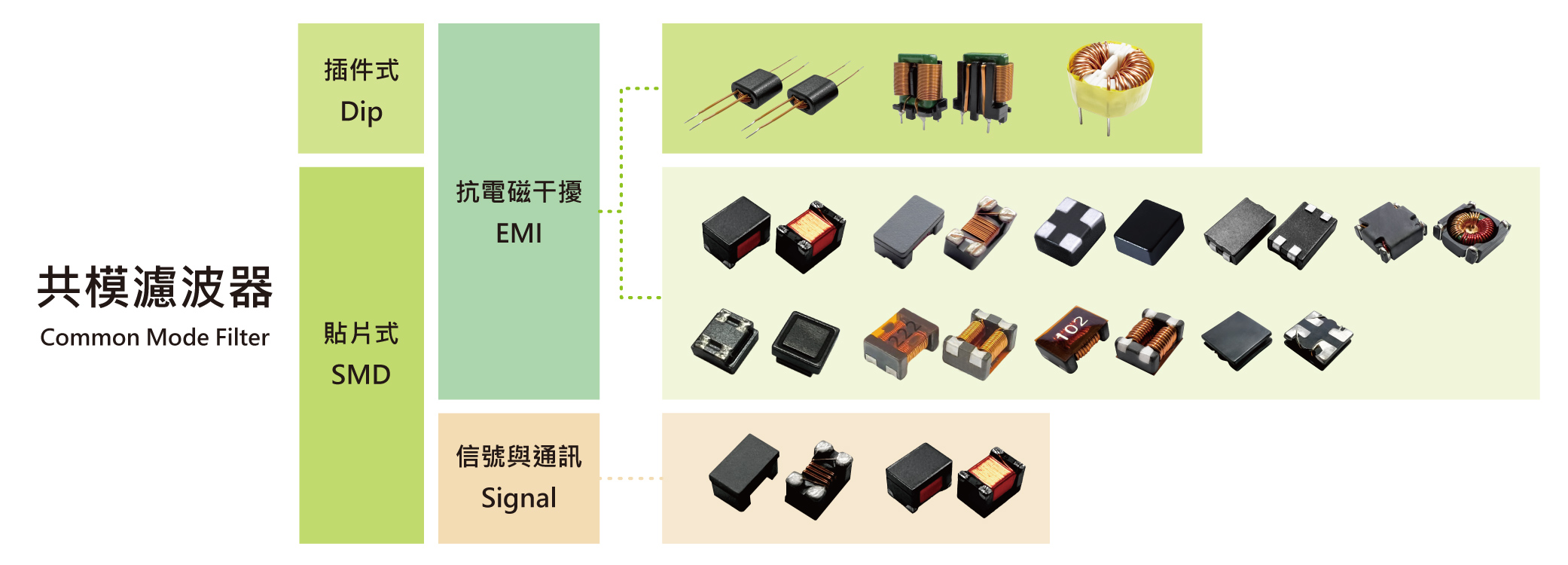

▶ Common Mode Filters Product Lineup

2. Material Selection for Common Mode Chokes

For power supply common mode chokes, the material selection is critical. The normal operating frequency of switching power supplies is above 20 kHz, while the harmful noise frequencies produced by the power supply typically range from 100 kHz to 50 MHz. The primary core materials used for power supply common mode chokes include Mn-Zn ferrite, iron powder cores, Sendust (iron-silicon-aluminum), H-FLUX (iron-nickel powder), MPP (molybdenum permalloy powder), and amorphous or nanocrystalline materials.

.jpg)

For signal common mode chokes, which are used in high-speed signal lines with operating frequencies above 10 MHz, the preferred material is usually Ni-Zn ferrite. This material choice is suitable for maintaining signal integrity while effectively suppressing high-frequency noise.

3.Key Design Considerations for Power Supply Common Mode Chokes

• Inductance Value Definition: The inductance value is calculated and defined based on the AL value of the core, either as a center value or a minimum value.

The calculation formula is : L= N2 * AL.

For example, if ui = 12000 and the number of turns is 20, the calculation is : T12000 X 20 X 20 = 4,800,000 nH = 4800 uH = 4.8 mH.

This value represents the center value, and can be defined according to the tolerance of the core, or the minimum value can be defined by calculating the smallest tolerance.

• Application Requirements Definition : Based on the customer's frequency requirements, it's important to determine whether they need a focus on the impedance (Z value) or the inductance value. A general guideline is: below 1 MHz, the inductance value is prioritized, while above 1 MHz, the Z value becomes the focus.

• Z Value : The impedance (Z value) is influenced by factors such as wire diameter, number of turns, material, and frequency.

• Inductance Requirements : Generally, the higher the inductance, the better, as a higher inductance improves the demagnetization performance.

• EMI (Electromagnetic Interference) : EMI is defined as any electromagnetic phenomenon that may cause a decrease in the performance of a device, equipment, or system, potentially resulting in damage to both living and non-living matter. EMI can manifest as electromagnetic noise, unwanted signals, or changes within the transmission medium itself. The main cause of radiated interference from the transmission medium is the use of high-frequency energy and signal modulation. Proper shielding can be employed to reduce electromagnetic interference.

• EMC (Electromagnetic Compatibility) : EMC refers to the overall ability of a device to function properly in its electromagnetic environment without introducing intolerable electromagnetic disturbances to anything in that environment. It encompasses both EMI (electromagnetic interference) and EMS (electromagnetic susceptibility).

• EMS (Electromagnetic Susceptibility) : EMS measures the ability of an electronic device to resist external electromagnetic interference. It reflects the level of immunity of the product to electromagnetic fields.

4.Key Design Considerations for Signal Common Mode Chokes

In addition to their application in power lines, common mode chokes are also frequently used on high-speed signal lines, such as USB 3.0, HDMI, LAN, and various LVDS signal lines like CAN BUS, SPI, RS232, and RS485. When used on signal lines, common mode chokes not only serve the purpose of suppressing common mode noise—for instance, to meet the common mode rejection ratio required by certain communication standards—but their most significant benefit often comes from their current compensation effect. As mentioned earlier, they function as current-compensated common mode chokes.

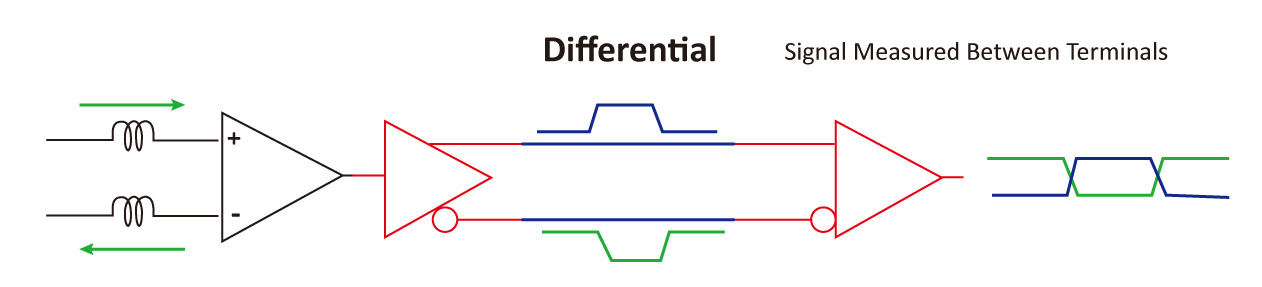

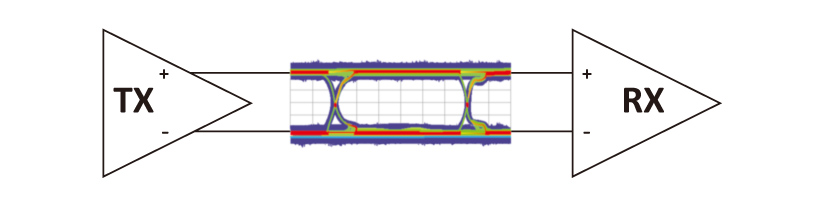

LVDS Differential Signal Transmission Diagram

As shown in the diagram above, unlike single-ended signaling, where a single signal wire is used for transmission, differential signaling transmits signals over two wires. These two signals have equal amplitudes, a 180-degree phase difference, and opposite polarities, forming a coupled signal.

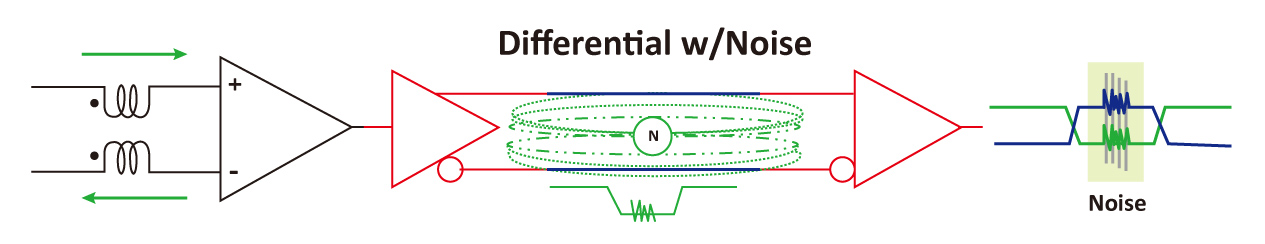

LVDS Differential Signal Noise Diagram

As illustrated in the diagram above, high-speed signal lines typically use differential signaling for transmission. Signal lines exhibit resistance, stray capacitance, and distributed inductance. While twisted-pair wiring effectively reduces stray capacitance, it cannot eliminate distributed inductance. As a result, there is differential-mode input inductance at the receiving end, and coupling currents on the line contribute to noise, as shown in the signal diagram.

Due to the symmetry of the transmission lines, these noise components are distributed nearly equally across both ends of the receiver. Placing a common-mode choke at the receiver’s input location allows the nearly equal noise signals to couple through the windings of the common-mode choke and cancel each other out. This significantly reduces coupled noise, achieving a noise reduction effect through current compensation at the receiver's input.

LVDS Differential Signal Testing and Optimization

LVDS Differential Signal Eye Diagram Illustration

As shown in the diagram above, LVDS differential signal testing and optimization typically use eye diagram techniques. The application of eye diagrams in LVDS signal testing is primarily reflected in the following aspects :

Signal Quality Assessment : The eye diagram is an essential method for signal integrity testing. By sampling and reconstructing the waveform of high-speed digital signals, it intuitively displays characteristics such as clock, data, and noise. This allows for the evaluation of the signal’s transmission quality. The shape and openness of the eye diagram directly reflect the signal's integrity and reliability.

Jitter Analysis : In LVDS signal testing, jitter is one of the key factors affecting signal quality. Eye diagrams assist engineers in identifying and quantifying jitter within the signal, offering an in-depth analysis of signal timing characteristics. This analysis helps understand the sources of jitter and implement corresponding optimization measures.

Template Testing : By comparing the signal against a predefined eye diagram template, engineers can quickly determine whether an LVDS signal meets specific industry standards or design specifications. This approach significantly simplifies compliance testing processes, ensuring consistency and repeatability of test results.

Automated Testing : Modern testing equipment, such as oscilloscopes, often comes equipped with automation capabilities for eye diagram testing and jitter analysis, greatly improving testing efficiency. For instance, TekExpress software can automatically configure test parameters, perform multiple test iterations, and generate detailed test reports.

Fault Localization : Eye diagram testing helps pinpoint signal quality issues, especially when template testing fails. It can highlight specific bit failure locations, enabling engineers to efficiently troubleshoot and resolve faults.

5、 Applications and Structural Classifications of Common Mode Chokes

Common mode chokes are primarily used in two-wire or differential systems, such as 220V mains power, CAN bus, USB signals, HDMI signals, and more. They are employed to filter out common mode interference while minimizing attenuation of the useful differential signals.

▶ Common Mode Filters Product Lineup

6.Conclusion

Although common mode chokes are named "inductors," they are quite different from power inductors. They do not require considerations for saturation current, nor are they designed for energy storage. The term "Choke" in their English name highlights their primary function, which is to choke or suppress unwanted currents. This choking effect is what allows them to effectively filter out noise, which is why they are also referred to as common mode choke coils.

GOTREND Technology offers a comprehensive range of common mode inductors for power and signal applications. With complete specifications and exceptional quality, our products are designed to meet diverse requirements across commercial, industrial, automotive, medical, and rail transportation applications. For inquiries, please contact our sales team at service@gotrend.com.tw.

Related articles :

• What is a Flyback Transformer?

• Ferrite Wire-Wound Inductors【GNLD Series】Enhance Power Conversion Efficiency

• Advantages and Disadvantages of Adding Nitrogen in SMT Reflow Ovens

GOTREND Technology Co., Ltd.

GOTREND Technology Co., Ltd.