TEST1

![]() 2025.2.24

2025.2.24

New Products

New Products

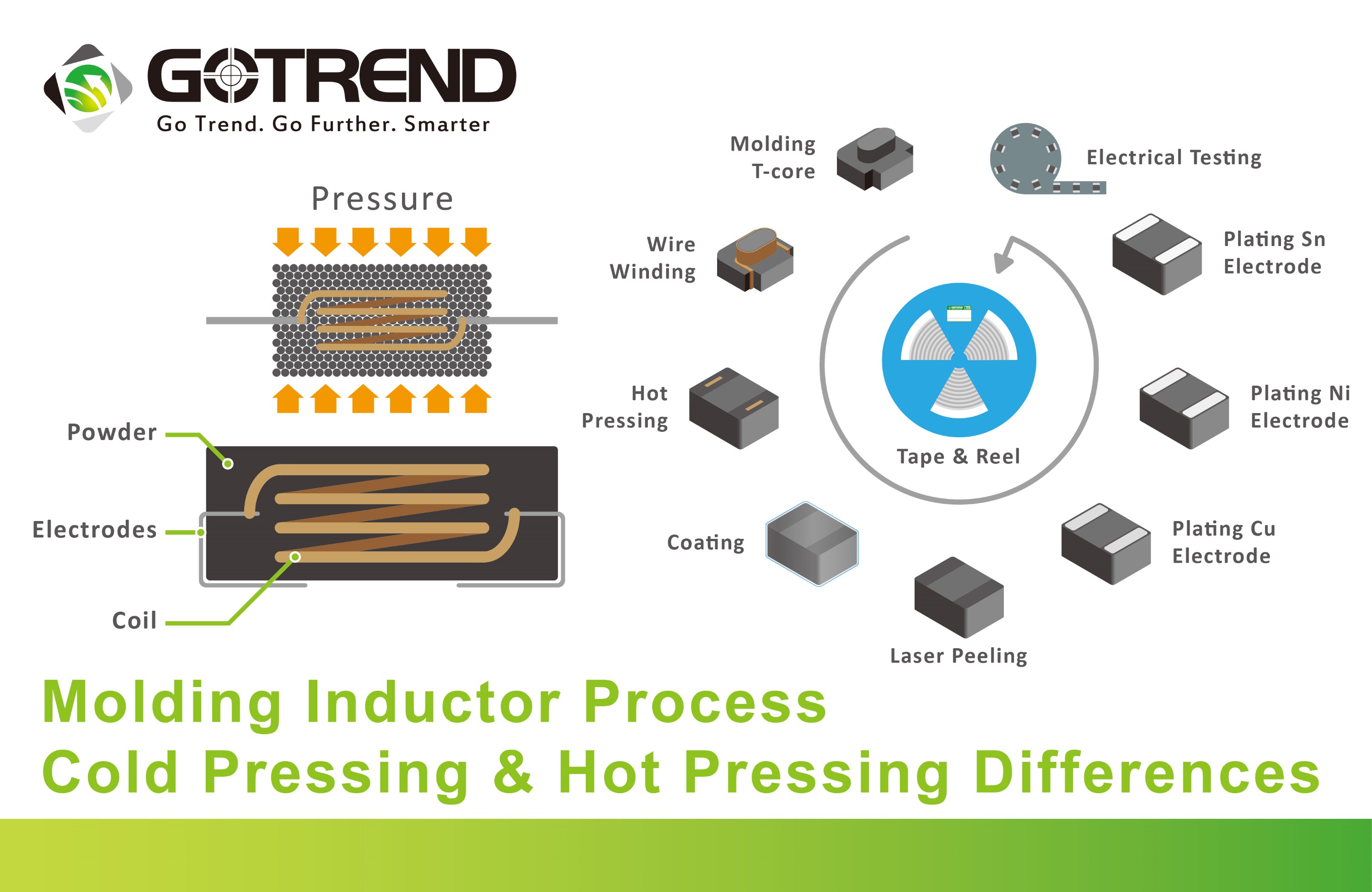

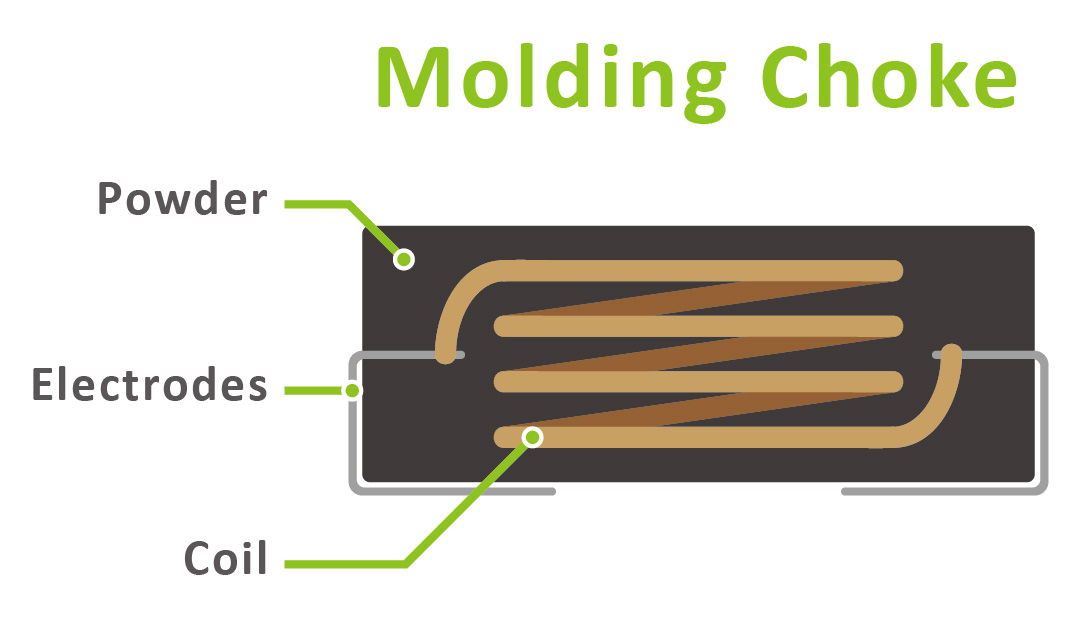

1、What is an molded inductor?

Molded inductor (Molding Choke) consists of a base and a winding body. The base embeds the winding body in metal magnetic powder through pressure casting. SMD pins are directly formed on the surface of the base as leads for the winding body (as shown in Figure 1).

( Figure 1 )

2、Features and advantages of molded inductor

Molded inductors, due to their superior stability, possess the following characteristics: miniaturization, high quality, high energy storage, and low resistance.

2.1 Performance and stability

Compared with conventional chip inductors, molded inductor have excellent resistance to large currents and high temperatures, and their stability in circuits is also outstanding. Compared with ordinary traditional assembled chip inductors, it has better reliability and stability, and is widely used in security, automotive, medical, aerospace and other high-tech fields.

2.2 Structural construction

Molded inductor is made of metal powder pressing, and the structure is simple, suitable for automated production. The coil is fully enclosed and closed-circuit design, which can meet the diverse needs of customers.

2.3 Technology and price

The workmanship of molded inductor is much more complex than that of traditional chip inductors, so the product yield rate is lower than that of traditional chip inductors, so its price is higher than that of traditional chip inductors.

However, with the continuous improvement of molded inductor production and R&D technology and the continuous upgrading of automation equipment, the price of molded inductor will become lower and lower, and it has gradually become the first choice of mainstream customers.

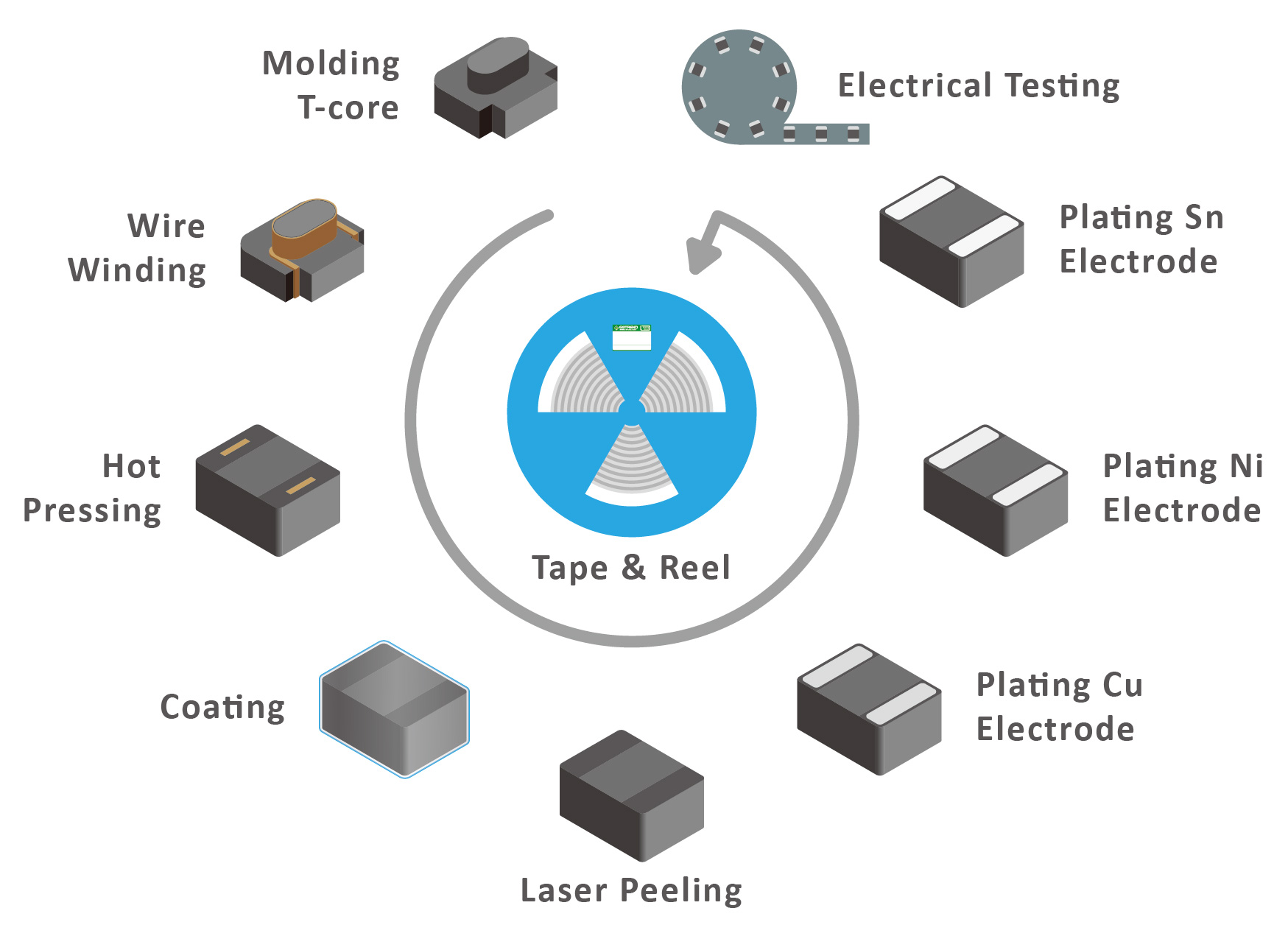

3、Process description of molded inductor

At present, there are two mainstream process processes for molded inductor : cold pressing process and hot pressing process.

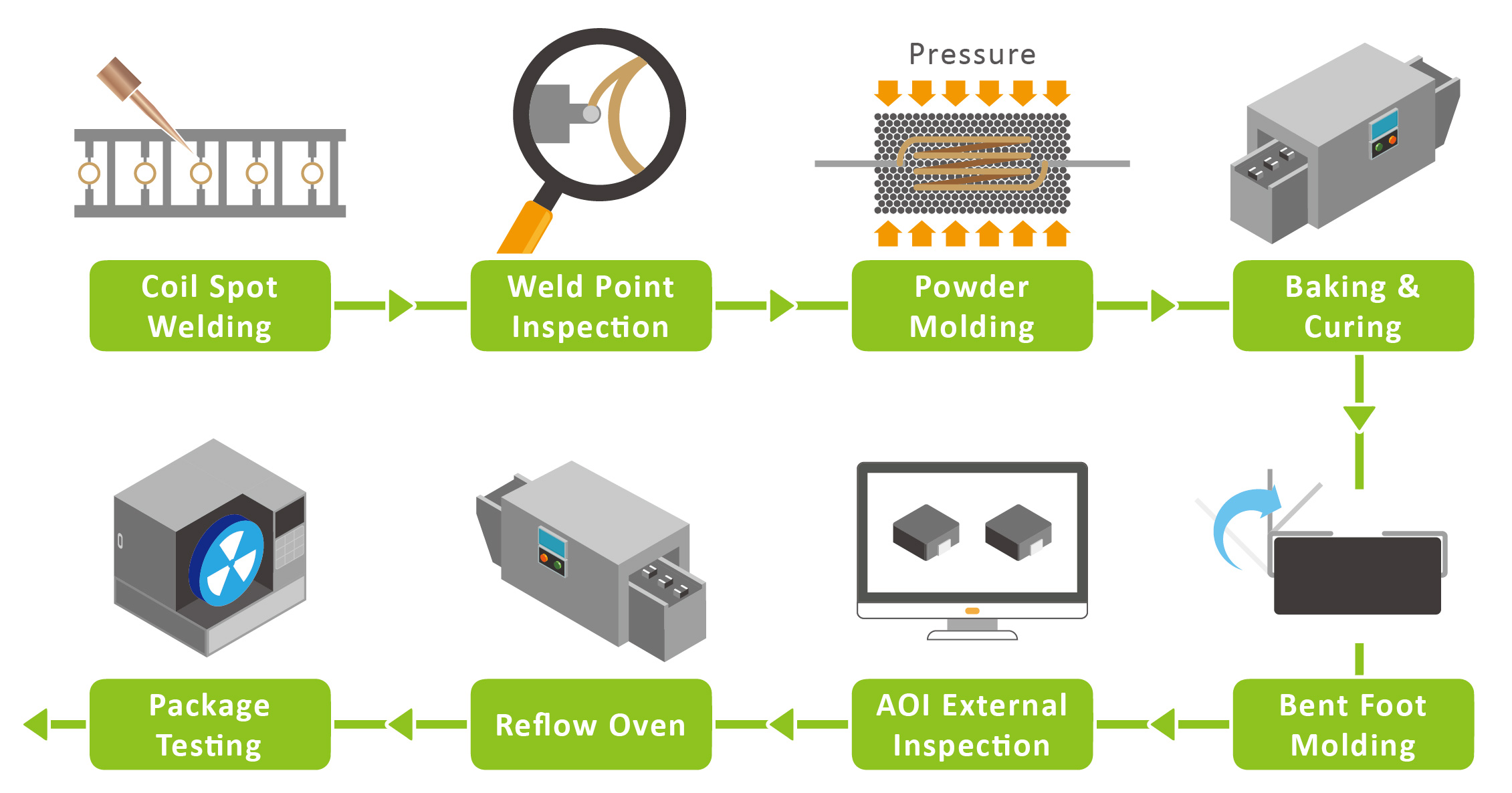

3.1 Cold pressing process :

The early mainstream process as an molded inductor currently mainly appears on large-size molded inductors, which have the advantages of mature process, stable equipment and high production efficiency.

Cold pressing process production flow chart

3.2 Hot pressing process :

With the increasing demand for inductor miniaturization in the market, the molded inductor process is also developing in the direction of small size, but the traditional cold process has certain limitations in the small size process, and the introduction of hot pressing process solves the problem of integral miniaturization.

Hot pressing process production flow chart

3.3 The comparison of cold pressing and hot pressing processes of molded inductors is as follows :

.jpg)

4、Classification and description of GOTREND Technology’s molded inductors

▶ Molded Inductor Series Specification Search

| Series | GSTC | GSTD | GSTM | GSTL | GSFM | GSTM2 | GSTG | GSTJ | GSFH | GSFT |

|---|---|---|---|---|---|---|---|---|---|---|

| Launch Time | 2008 | 2012 | 2014 | 2020 | 2021 | 2023 | 2023 | 2023 | 2023 | 2023 |

| Powder Material | Alloy & Carbonyl | Alloy | Carbonyl | Alloy | Alloy | Carbonyl | Alloy | Alloy | Carbonyl | Amorphous |

| Powder Source | Germany BASF | China | China | China | China | China | China | China | China | China |

| Wire Type | Round | Round | Round | Round | Flat Wire | Round | Round | Round | Flat Wire | Flat Wire |

| Terminal PAD Type | Hoop | Hoop | Hoop | Hoop | Direct Wire PAD | Hoop | Hoop | Hoop | Direct Wire PAD | Direct Wire PAD |

| Exterior Coating | Gray color epoxy | No coating | Light clear epoxy | No coating | No coating | Light clear epoxy | No coating | No coating | Light clear epoxy | Light clear epoxy |

| Rust Resistance |

★★★★ |

★★★★ |

★★★★★ | ★★★★ | ★★★ | ★★★★★ | ★★★ | ★★★★ | ★★★ | ★★★ |

| Application | Follow Vishay、 Cyntec , the first series | •Low cost •Popular in consumer application. •Launch for replace GSTC |

•Popular in the IPC、Automotive •competitively priced against the GSTC •Excellent rust resistance |

Especially suitable for low DCR | •Especially suitable for low DCR •Higher price |

•Popular in the IPC、automotive •Competitively priced against the GSTC •Excellent rust resistance |

•Popular in the IPC、automotive •Competitively priced against the GSTC |

•Popular in Consumer application. •Low Cost, the best choice for alternative materials. |

It adopts hot pressing process to achieve excellent performance and high reliability quality of small size, large current, low impedance, and AEC Q-200 certification. | |

| Crossing reference | TDX SPM-DVZ , SPX-V Series | VishaX IHLX-Series |

TDX SPM-DVZ , SPX-V Series | VishaX IHLX-Series |

EATOX EXLA-Series , CoilcrafX XEL-Series | TDX SPM-DVZ , SPM-V Series | VishaX IHLX-Series |

VishaX IHLX-Series |

PulsX ADCC-Series | PulsX ADCC-Series |

| Price Level | ★★★★ | ★★ | ★★★ | ★★★ | ★★★★★ | ★★★ | ★★ | ★★ | ★★ | ★★★ |

| Delivery | 8~12 Weeks | 4~8 Weeks | 4~8 Weeks | 6~10 Weeks | 8~12 Weeks | 8~12 Weeks | 4~8 Weeks | 4~8 Weeks | 4~8 Weeks | 8~12 Weeks |

| Shipment Ratio | 30% | 32% | 32% | 5% | 1% | 32% | 2% | 1% | 1% | 5% |

| Size | GSTC | GSTD | GSTM | GSTL | GSFM | GSTM2 | GSTG | GSTJ | GSFH | GSFT |

|---|---|---|---|---|---|---|---|---|---|---|

| 141265 | V | |||||||||

| 141208 | V | V | ||||||||

| 160808 | V | V | ||||||||

| 201206 | V | |||||||||

| 201208 | V | V | ||||||||

| 201210 | V | V | ||||||||

| 201608 | V | V | ||||||||

| 201610 | V | V | V | V | ||||||

| 201612 | V | |||||||||

| 252008 | V | |||||||||

| 252010 | V | V | ||||||||

| 252012 | V | V | V | V | ||||||

| 322510 | V | |||||||||

| 322512 | V | V | ||||||||

| 322520 | V | V | ||||||||

| 3012 | V | V | ||||||||

| 353220 | V | V | V | |||||||

| 4010 | V | |||||||||

| 4012 | V | V | ||||||||

| 4020 | V | V | V | V | V | V | V | V | ||

| 4030 | V | V | ||||||||

| 5012 | V | |||||||||

| 5015 | V | |||||||||

| 5018 | V | V | ||||||||

| 5020 | V | V | V | V | ||||||

| 5030 | V | V | V | V | V | V | ||||

| 5050 | V | |||||||||

| 6010 | V | |||||||||

| 6012 | V | |||||||||

| 6015 | V | V | V | |||||||

| 6018 | V | V |

| Size | GSTC | GSTD | GSTM | GSTL | GSFM | GSTM2 | GSTG | GSTJ | GSFH | GSFT |

|---|---|---|---|---|---|---|---|---|---|---|

| 6020 | V | V | V | |||||||

| 6024 | V | V | V | |||||||

| 6030 | V | V | V | V | V | V | V | |||

| 6040 | V | V | V | |||||||

| 6050 | V | V | V | V | V | |||||

| 6060 | V | |||||||||

| 7020 | V | |||||||||

| 7030 | V | |||||||||

| 7050 | V | |||||||||

| 7070 | V | |||||||||

| 8017 | V | |||||||||

| 8045 | V | |||||||||

| 8080 | V | |||||||||

| 1030 | V | V | ||||||||

| 1040 | V | V | V | V | V | V | ||||

| 1045 | V | |||||||||

| 1050 | V | V | V | V | ||||||

| 1060 | V | |||||||||

| 1010 | V | |||||||||

| 1235 | V | |||||||||

| 1238 | V | |||||||||

| 1250 | V | V | V | V | V | |||||

| 1260 | V | V | V | V | ||||||

| 1265 | V | V | ||||||||

| 1350 | V | |||||||||

| 1580 | V | V | ||||||||

| 1510 | V | |||||||||

| 1513 | V | |||||||||

| 1770 | V | V | V | V | ||||||

| 2313 | V |

Related articles :

• Evolution of Molding Inductor-Low DCR , High Saturation Current 【GSNH Series】

• Analysis of the Relationship between Inductor Q-Factor and ACR

• What is an inductor? What is the definition of an inductor? Overview of inductor characteristics, parameters, and types.

t

t