What does the color of the inductor ring mean?

![]() 2022.10.19

2022.10.19

Articles

Articles

Magnetic ring is a common kind in inductors, general power inductors, common mode inductors will use magnetic rings to wind the coil. Magnetic ring coatings will have different colors, different materials, so how do we distinguish them?

Let's take a look at what the common types and colors of magnetic rings represent.

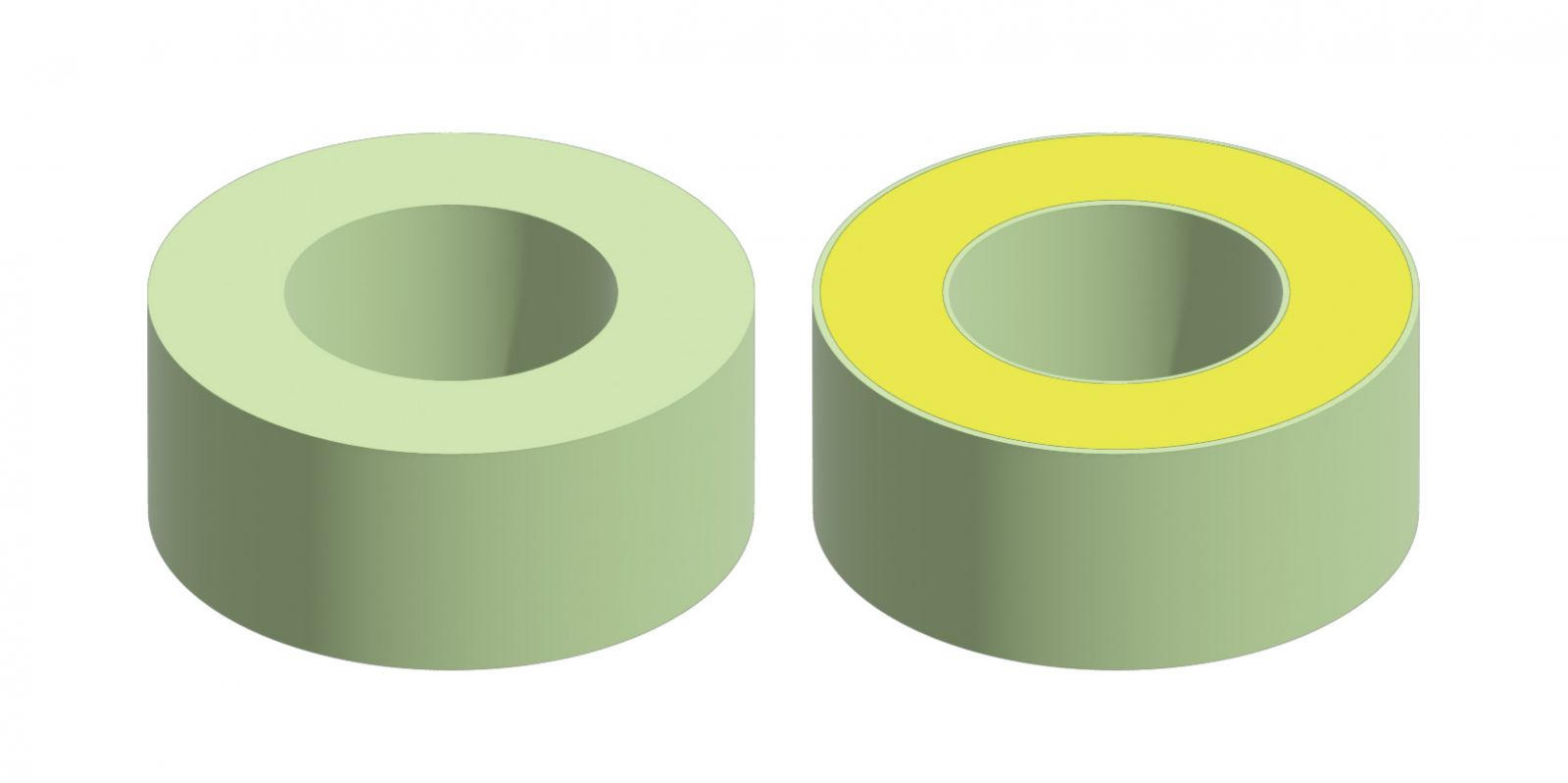

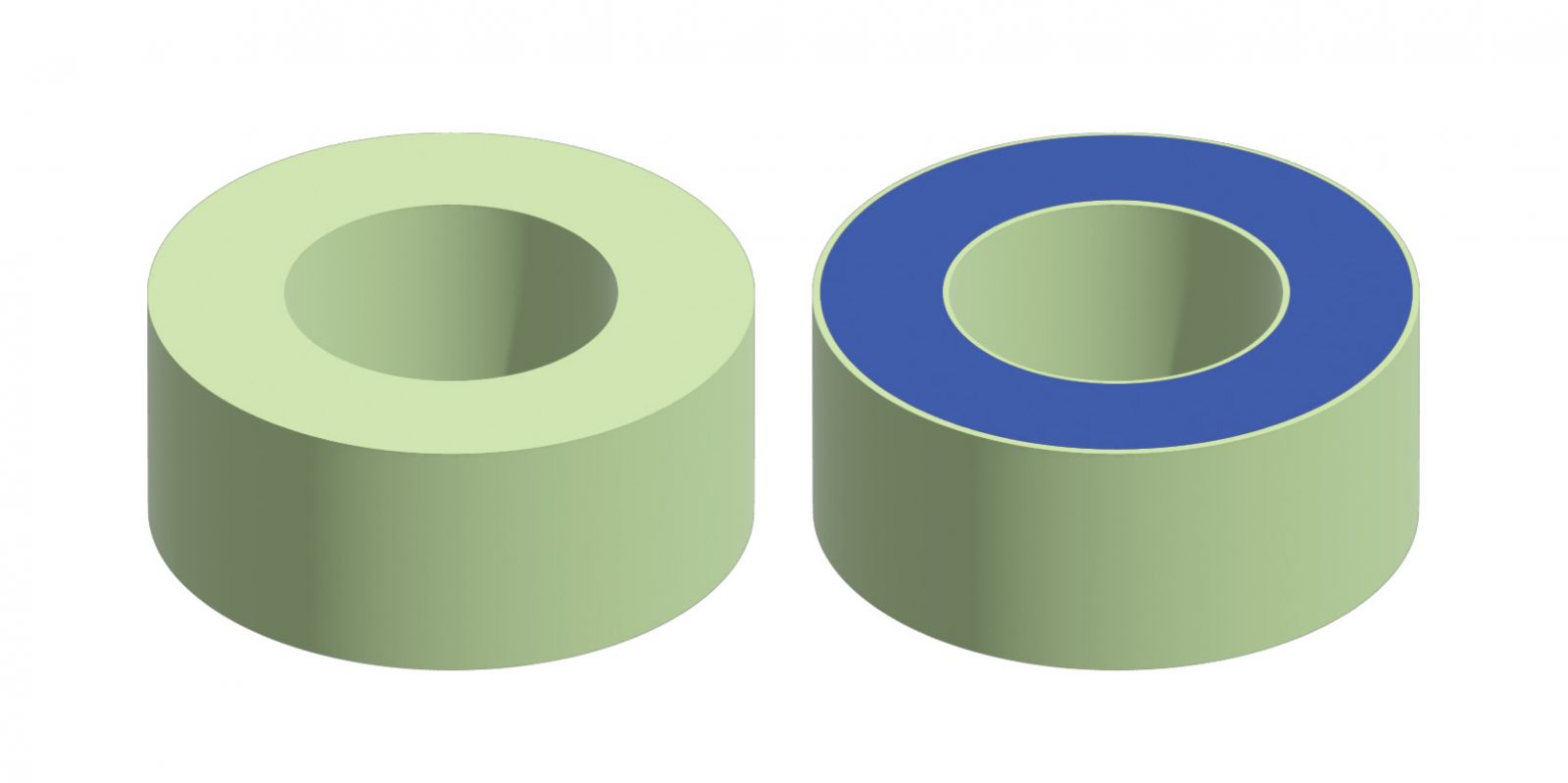

Most of the magnetic rings of the inductor need to be painted, easy to distinguish, the general iron powder core with two colors to distinguish, commonly used are red / transparent, yellow / red, green / red, green / blue and yellow / white, etc., manganese core ring is generally coated green, iron silicon aluminum is generally all black and so on.

In fact, the color after the magnetic ring firing has nothing to do with the dyeing of the paint sprayed after it, but it is just a convention in the industry.

For example, green represents a highly conductive ring; The two colors represent the iron powder core magnetic ring; Black represents the iron silicon aluminum magnetic ring and so on.

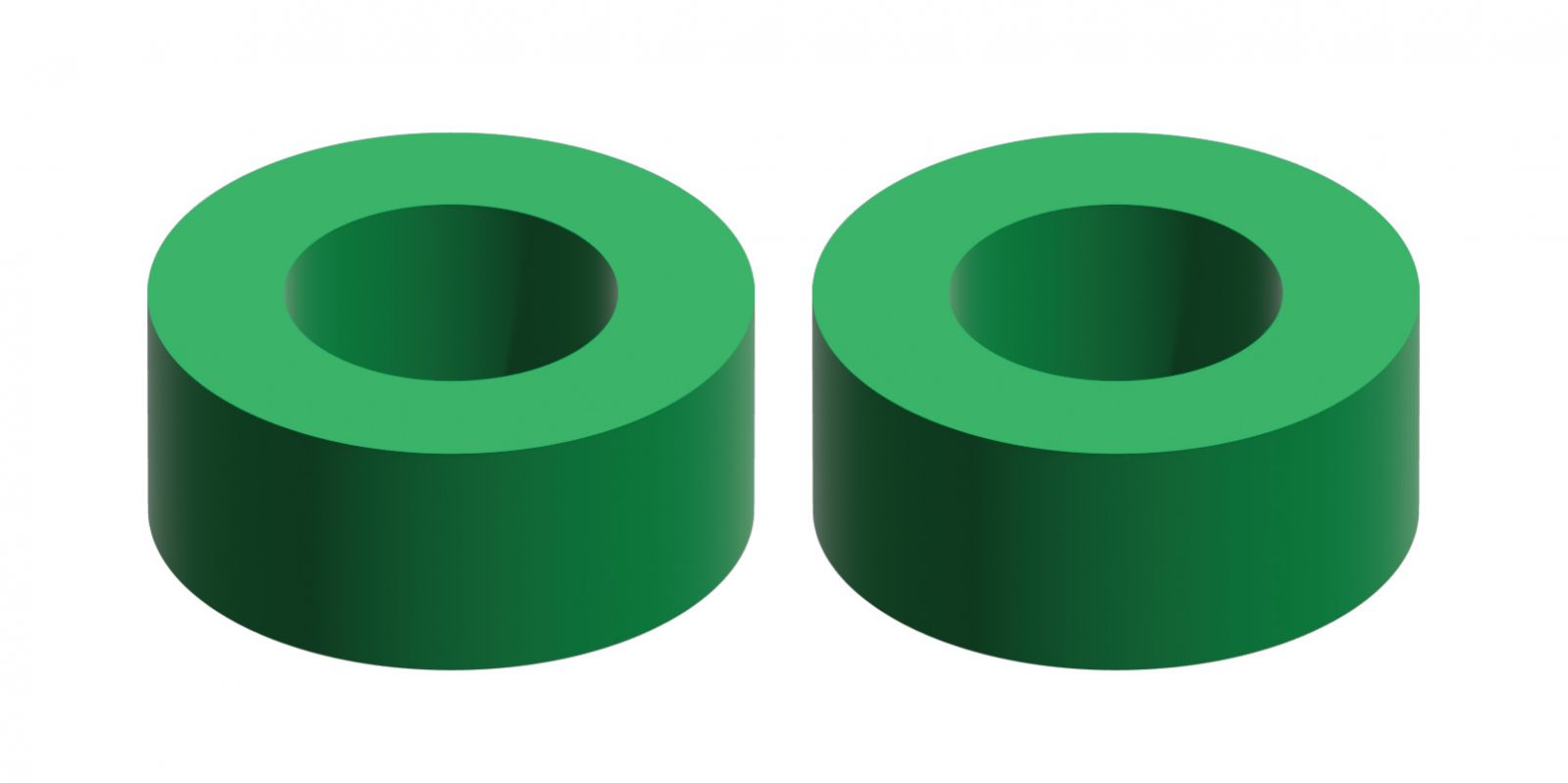

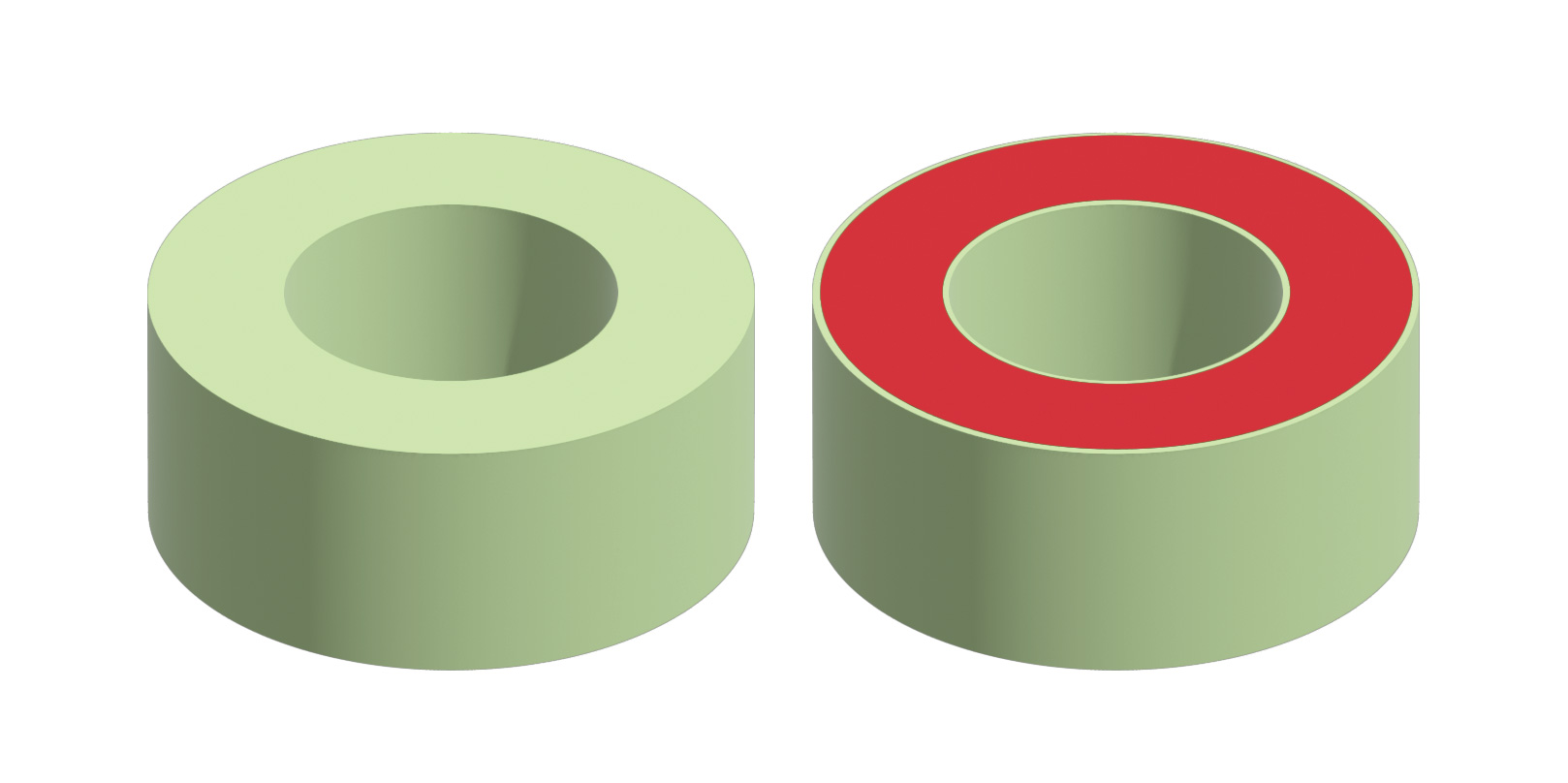

1. High conductivity ring

High conductivity ring, it has to be said that nickel zinc ferrite magnetic ring.

Magnetic ring is divided into nickel zinc and manganese zinc according to the material, the magnetic permeability of nickel zinc ferrite magnetic ring material is currently from 15-2000 have applications, the commonly used material is nickel zinc ferrite permeability between 100-1000, according to the permeability classification, divided into low permeability materials.

The magnetic permeability of the manganese zinc ferrite magnetic ring material is generally above 1000, so the magnetic ring produced by the manganese zinc material is called a high magnetic ring.

This type of magnetic ring is generally all painted green, unless the customer has a special purpose or custom.

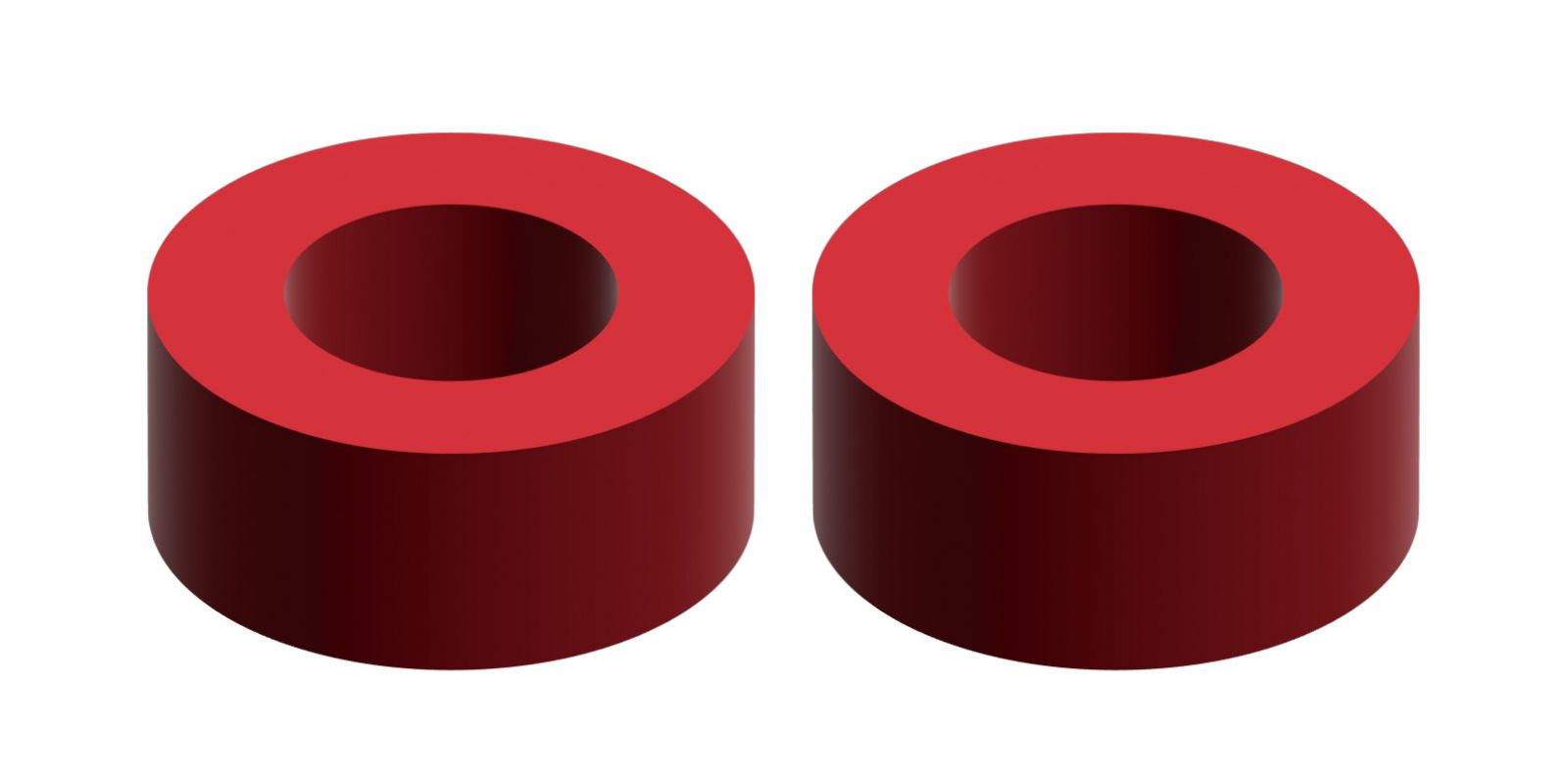

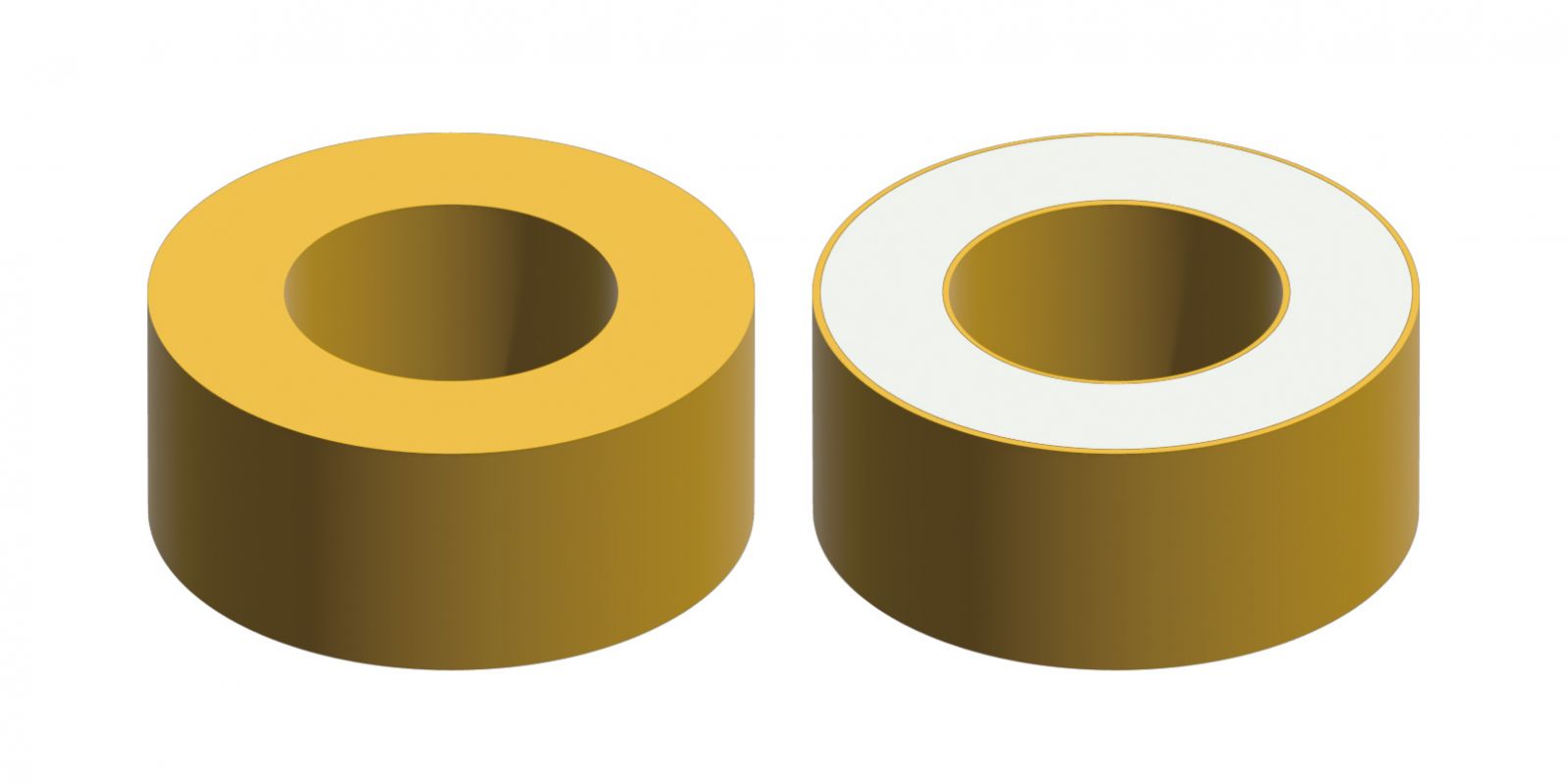

2. Iron powder core magnetic ring

Iron powder core is a popular term for the magnetic material ferric oxide, which is mainly used in electrical circuits to solve electromagnetic compatibility (EMC) problems. In practice, a variety of other substances are added according to the different filtering requirements in different bands.

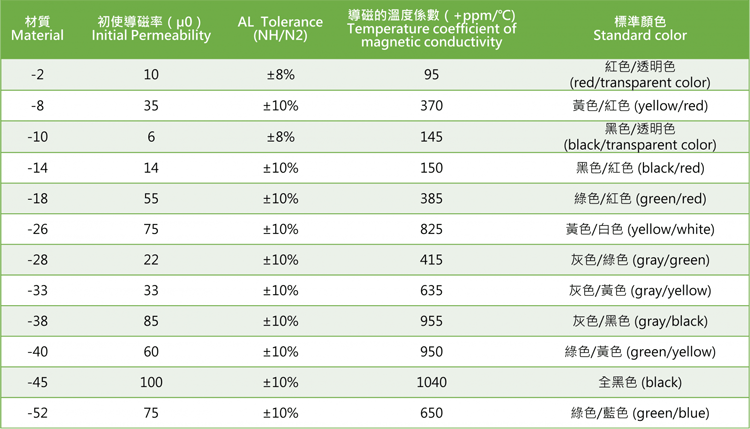

• 2 material:

red body,transparent (FERRITE natural color) bottom surface---- this material has a low permeability, and can reduce the AC flux density during operation than other materials without void loss.

• 8 material :

yellow body, red bottom surface, this material in the case of high deflection, low core loss, and good linearity, is a good high-frequency material, but also the most expensive material.

• 18 material :

light green body, red bottom surface, this material is the same as 8 materials, low core loss, but the permeability is higher and the cost is lower, and there are good DC saturation characteristics.

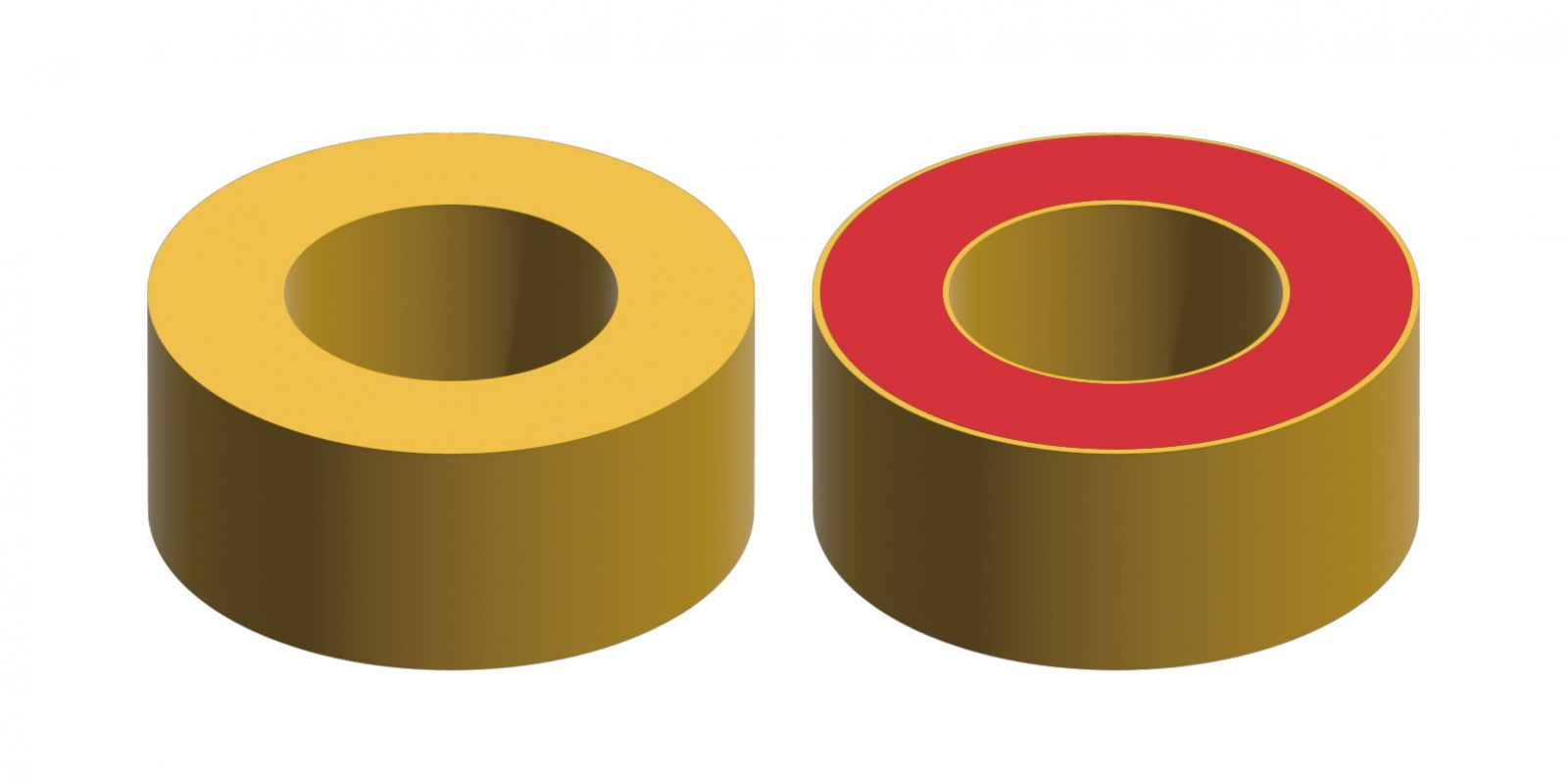

• 26 material :

yellow body, white bottom surface, the most popular material, is a cost-effective general purpose material, suitable for a wide range of uses such as power conversion and line filtering.

• 28 materia l :

gray body, green bottom surface, with good linearity, low cost and relatively low permeability, widely used with large size high power UPS anti-current device.

• 33 material :

gray body, yellow bottom surface, is a kind of material that can replace 8 materials but is not expensive, suitable for cases where core loss is not important at high frequencies, and good linearity at high deflection.

• 40 material :

green body, yellow bottom surface, the cheapest material, its characteristics are quite similar to 26 materials, generally used in larger sizes.

• 52 material :

light green body, blue bottom surface, the material in the high frequency core loss is relatively low, and the permeability is the same as -26 material, in the new high frequency anti-current device widely used.

▶ Below is a brief table of the permeability, tolerance, temperature coefficient of the p ermeability, and standard color of more magnetic materials.

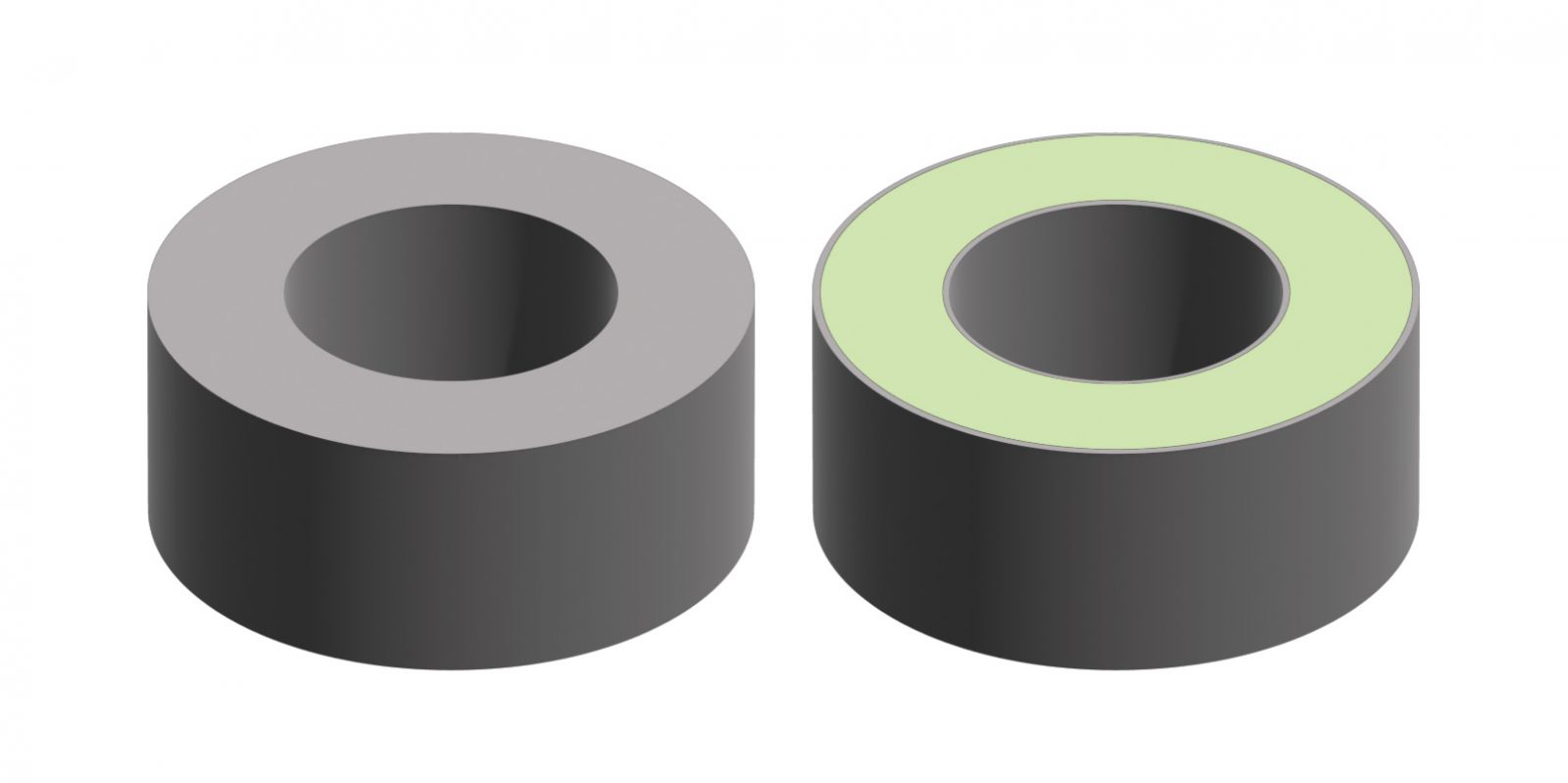

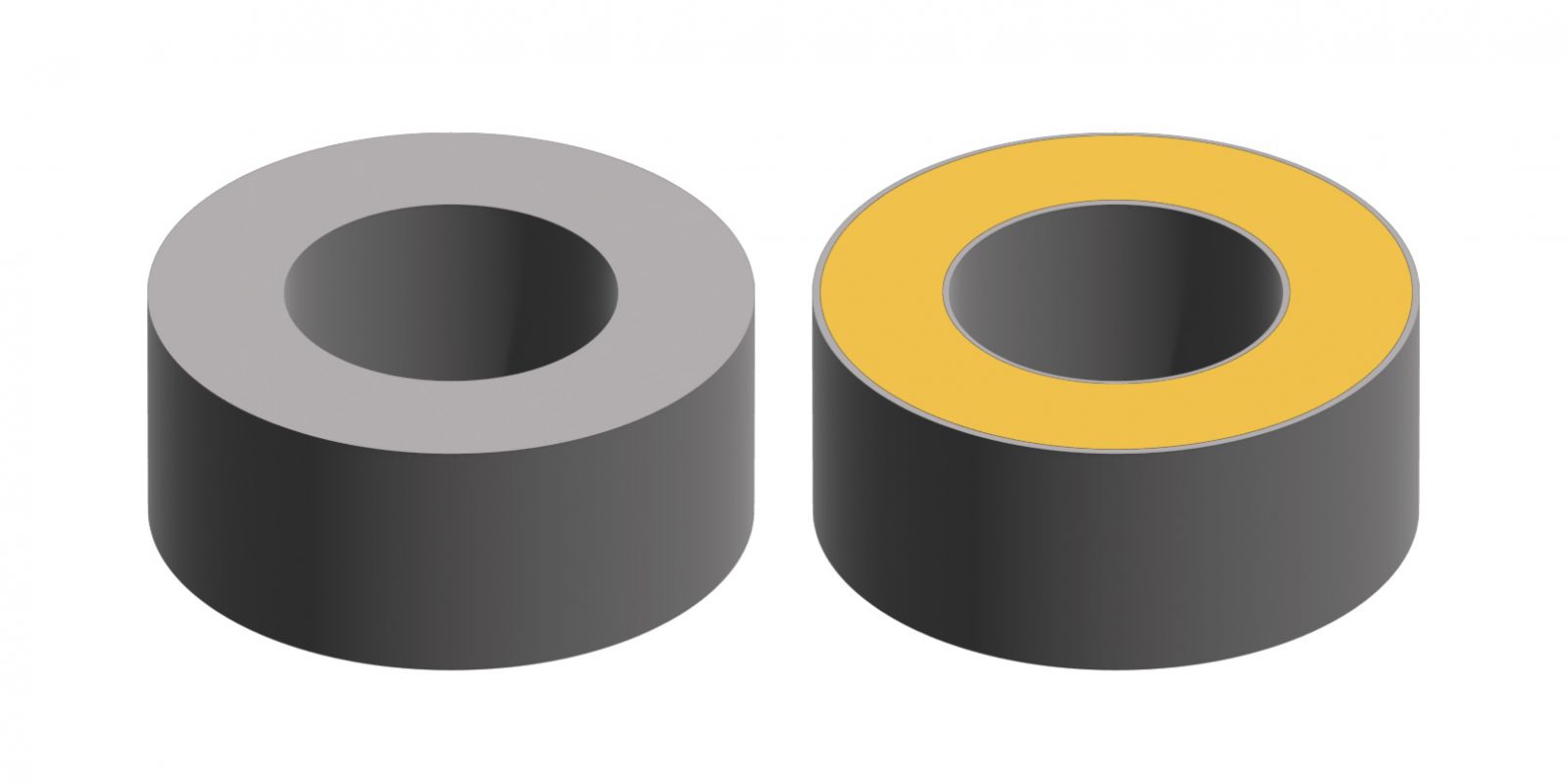

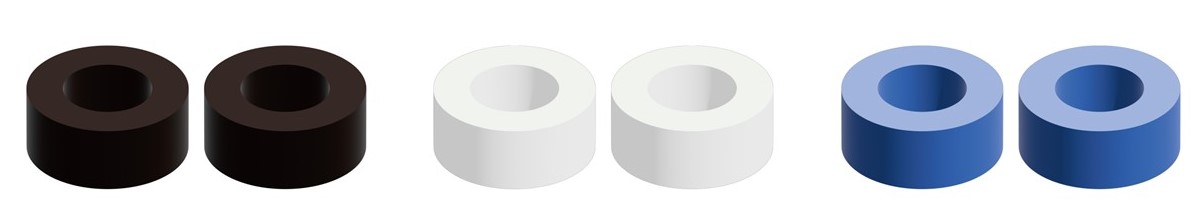

Iron silicon aluminum magnetic ring Ferrosilicon aluminum magnetic ring is one of the more used magnetic rings, in simple terms, ferrosilicon aluminum is composed of iron-silicon-aluminum, with a fairly high Bmax (Bmax is the average maximum magnetic flux density on the cross-sectional area of the core. ), its core loss is much lower than the iron powder core and high magnetic flux, there is low magnetostrictive (low noise), is a low-cost energy storage material, no heat aging, can be used to replace the iron powder core, at high temperature performance is very stable.

▶ Characteristics of the iron silicon aluminum magnetic ring :

lower than the iron powder core loss, good DC bias characteristics, the cost is between the iron powder core and the iron nickel molybdenum, the material permeability(μ)are : 26, 60, 75, 90, 125 iron silicon aluminum standard color is black, but also made of gray or blue.

Related articles :

• APPLE MagSafe tangle dancing with Qi2 MPP

• What is copper loss? What is the skin effect ? The difference between Isat and Irms

• What is an inductor?

GOTREND Technology Co.,Ltd

GOTREND Technology Co.,Ltd