Bias Tee Inductor Solutions for Automotive Cameras

![]() 2024.9.18

2024.9.18

Articles

Articles

1、 Introduction to the development trend of automotive cameras

With the advancement of the automotive industry, humanity is on the brink of entering the era of assisted and autonomous driving. By equipping vehicles with cameras and LiDAR systems, stable, reliable, and clear data about the surrounding environment can be obtained.

This ensures that vehicles can operate safely even in autonomous mode. Some countries have already mandated that new car models must be equipped with cameras. As cameras become more widespread and their numbers increase, their presence will inevitably impact the exterior and interior space of vehicles, making miniaturization increasingly necessary.

Compared to regular electronic cameras, automotive cameras operate in much harsher environments, such as vibration, high temperatures, water vapor, low temperatures, and dramatic changes in light. Given that automotive cameras are intended to enhance driving safety, they must consistently provide stable and reliable environmental data under all these conditions.

Therefore, as automotive technology advances, the performance requirements for automotive cameras will become increasingly stringent. Following the release of the "Automotive Camera Industry Standard" in 2019, automotive cameras are now required to operate continuously in environments ranging from -40°C to +85°C, resist water immersion, be magnetically shielded and shock-resistant, and have a lifespan of 8 to 10 years. Additionally, for safety reasons, automotive cameras must continue to function during short power interruptions, necessitating a comprehensive upgrade of their critical components.

.jpg)

2、 Key Performance Considerations for Automotive Camera Bias Tee

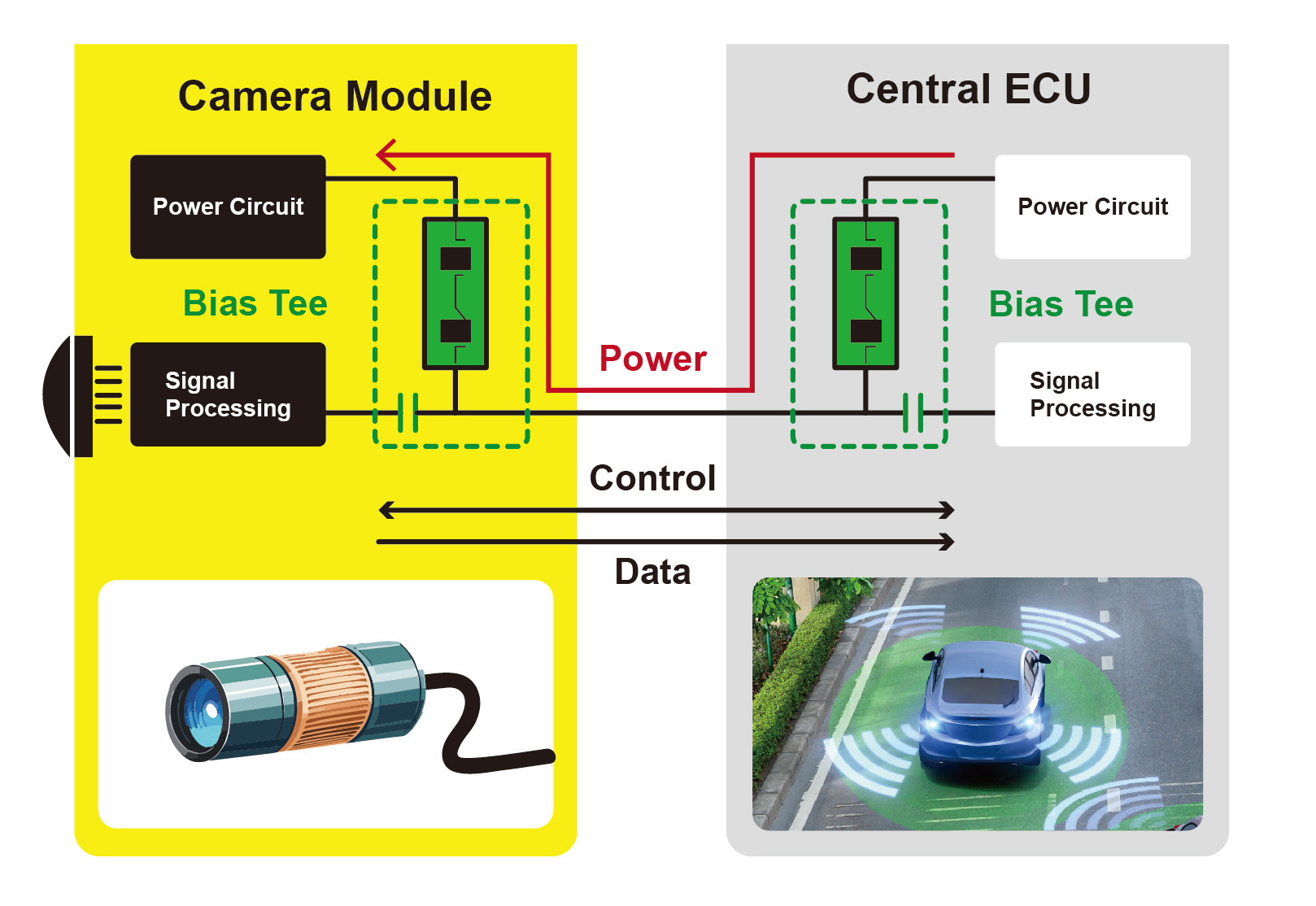

To ensure that the power circuit and signal circuit do not interfere with each other, a Bias Tee circuit is sometimes used, as shown in Figure 1. Typically, a Bias Tee consists of a series capacitor to prevent large DC currents from directly entering the signal processing unit and an inductor to prevent signal components from entering the power circuit unit.

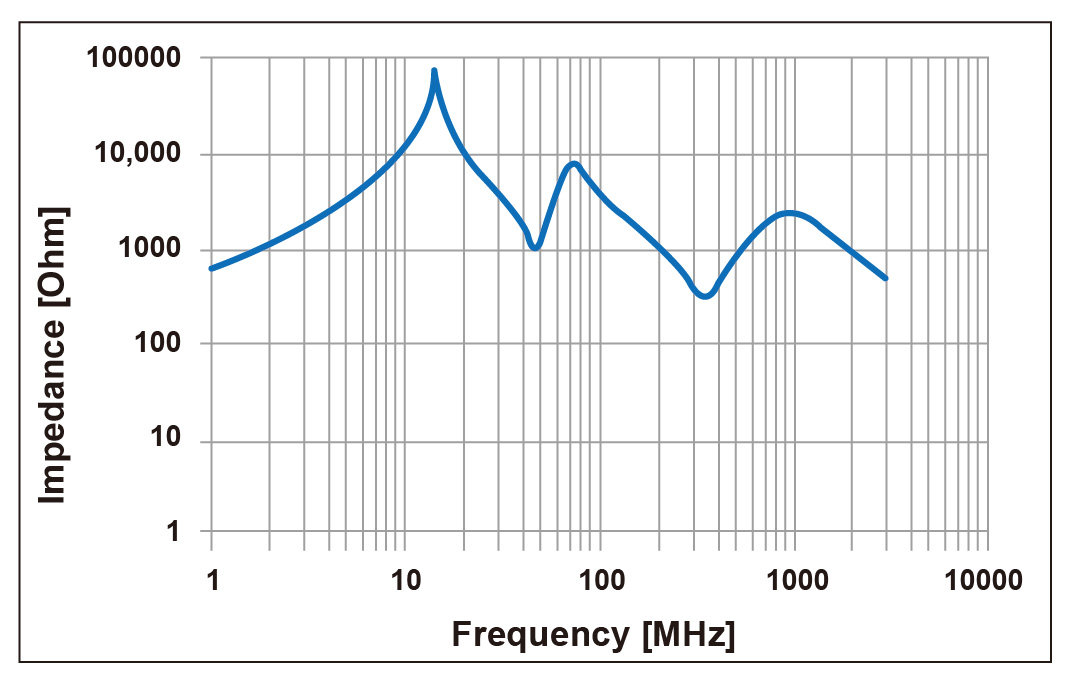

When designing for automotive cameras, it is essential to consider the necessary characteristics of the inductors. The signal components of automotive cameras include high-speed signals (several Gbps) for transmitting captured images and low-speed signals (several hundred k- to several Mbps) for control purposes. To prevent these signal components from entering the power circuit and to ensure effectiveness across a wide frequency range, it is necessary to combine multiple inductors with different characteristics. As shown in Figure 2, this is an example of the combined characteristics suitable for a Bias Tee. By combining these components, high impedance can be achieved across a range from several MHz to several GHz.

( Figure 1 )

( Figure 2 )

3、 GOTREND Inductor Recommendations for Automotive Camera Bias Tee

GOTREND leverages unique material capabilities and automated production techniques to achieve high and low impedance with high self-resonant frequency inductors in the GTLQH32PL-AE and GNLC1610PL-AE series. By combining these inductors, we create an optimal Bias Tee circuit.

The specifications for the High Q Inductor GTLQH32PL-AE and High Frequency Wound Inductor GNLC1610PL-AE series are as follows. By combining these small inductors with various characteristics, we can construct a Bias Tee circuit that closely matches the required performance.

.jpg)

Search by specification

.jpg)

Search by specification

GTLQH32PL-AE and GNLC1610PL-AE Series introduced here are ideal components for Bias Tee circuits in automotive cameras. Combining components with various impedance values to create a Bias Tee circuit with sufficient characteristics across the required frequency range is crucial.

GOTREND Technology Co., Ltd.

GOTREND Technology Co., Ltd.